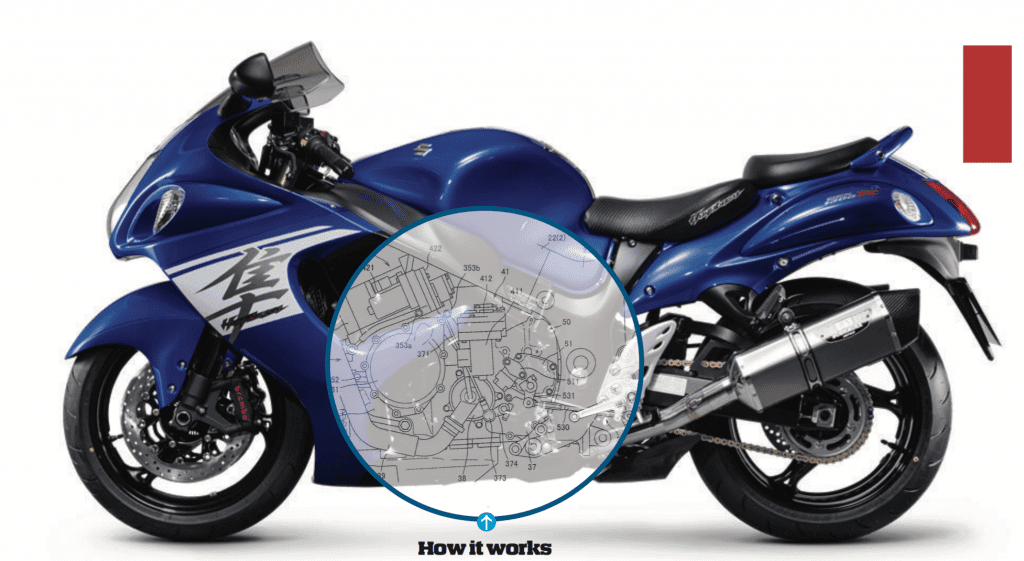

SUZUKI’S NEXT-GENERATION Hayabusa will feature

a semi-automatic transmission that dispenses with a conventional hand- operated clutch but keeps

a familiar foot-operated gearshift lever.

The company has filed a host of new patents around the system, clearly showing the set-up attached to a version of the existing GSX1300R engine.

While images show an outline of the existing Hayabusa, the drawings are more likely to be accurate

in their depiction of the engine, since a large number of the patents’ elements relate to the way the semi-

automatic gearshift system is attached, keeping it compact while preventing engine heat from damaging the electronics.

That fits with rumours from Japan that the next- gen Hayabusa will retain elements of the existing model. Engine capacity is expected to be increased to around 1440cc.

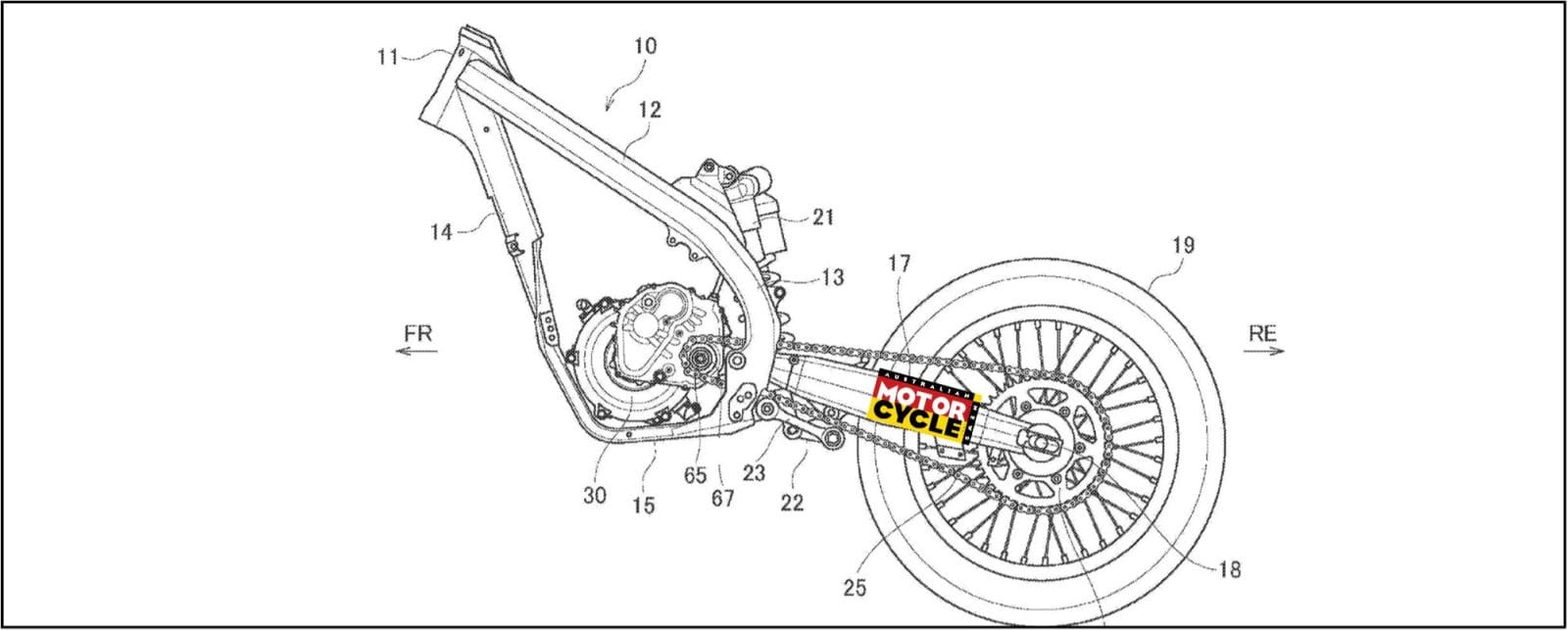

Importantly, the new semi-auto system is very much an external, bolt-on arrangement. It has three main components; a sensor that measures movement of the gear lever, an actuator that operates the clutch, and a second actuator that shifts the gears.

Despite the apparent extra components, the aemi-auto system adds nothing to

the width of the Hayabusa, and it also adds little to the manufacturing complexity of the bike.

When will we see the

new Busa? It won’t be too long now. The existing bike doesn’t meet the latest European type-approval legislation, which means it’s currently sold in Europe only under a period of grace that comes to an end on 31 December.

From 2019, Suzuki will need the new model to be on-stream if it’s to prevent a hiatus in Hayabusa sales.

Why do it?

THE ADVANTAGE IS that, while it will feel like a conventional gearshift, it hands the final control over to the bike’s computer. This means it can prevent shifts that would cause the engine to over-rev or stall, or that might cause the rear wheel to lock. Coupled with a ride- by-wire throttle, it should also ensure perfect rev-matching on downshifts and smooth, snatch-free power upshifts; important on a bike like the Hayabusa with its superbike- beating acceleration.

The system also opens the door to the possibility of a fully- automatic riding mode, which

could be easily implemented with simple software changes.

How it works

- A fake lever on the front sprocket cover incorporates a mechanism that creates a positive ‘click’, replicating the feel of a mechanical shift.

- When the pseudo gearshifter is moved up or down, a message is sent to the engine management system. A clutch actuator then engages or disengages the clutch.

- The gearshift actuator is a servo just like the clutch actuator, and is mounted alongside the cylinders; it operates the gear- shift mechanism via a rod.

By BEN PURVIS