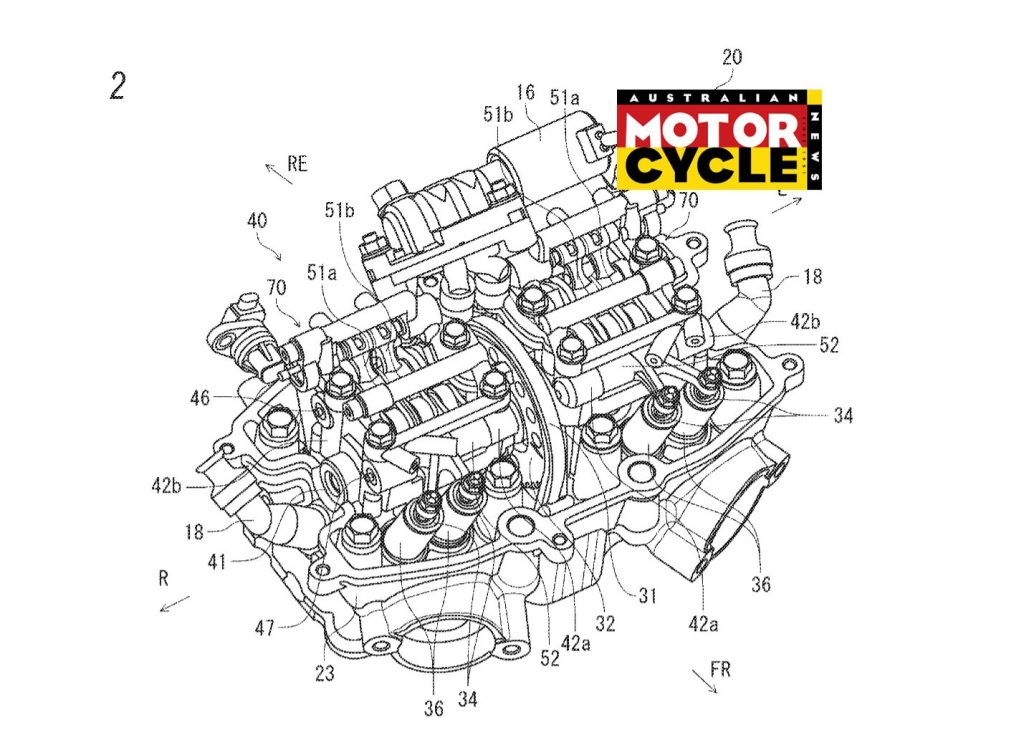

Suzuki is no stranger to variable valve timing (VVT) , having used an unusual, centrifugal cam-phasing system in its most recent GSX-R1000 models, but the new design uses an approach more like the old Honda VTEC system, with two sets of lobes for the intake valves and the ability to switch between them by using hydraulic pressure to insert or remove a locking pin.

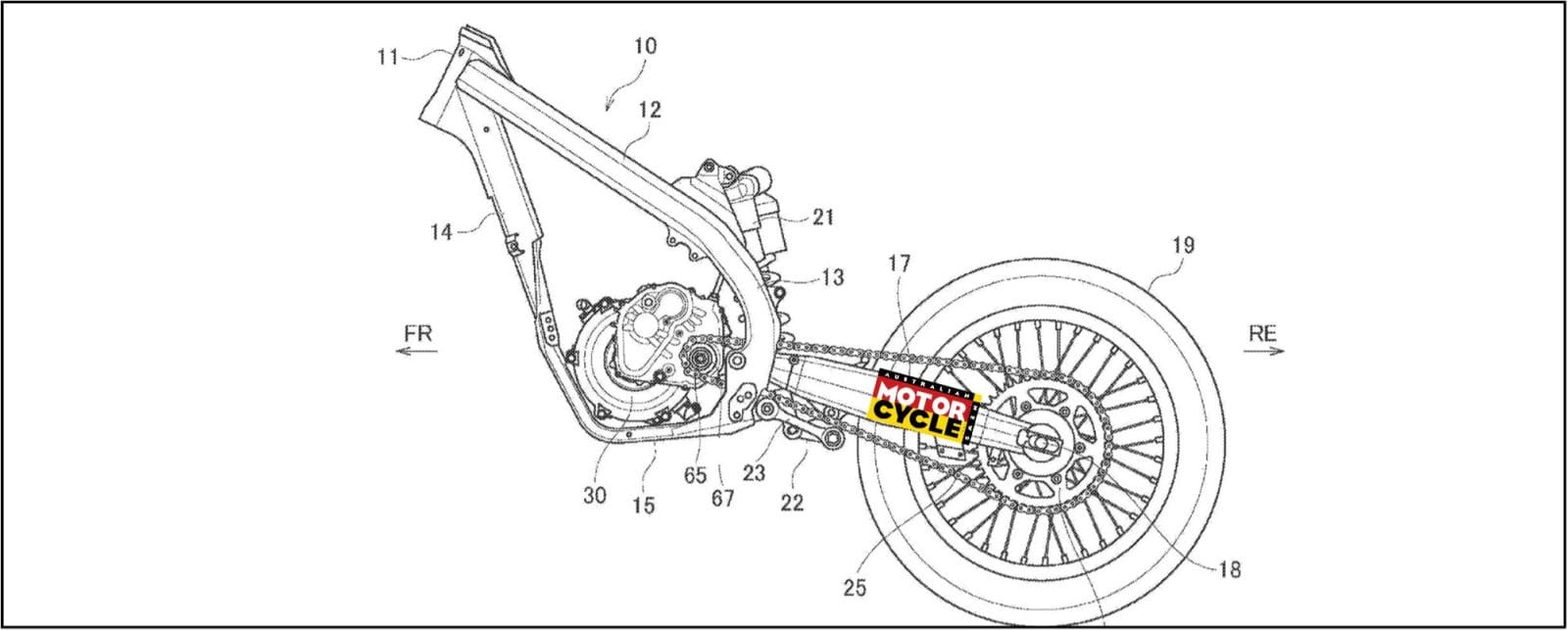

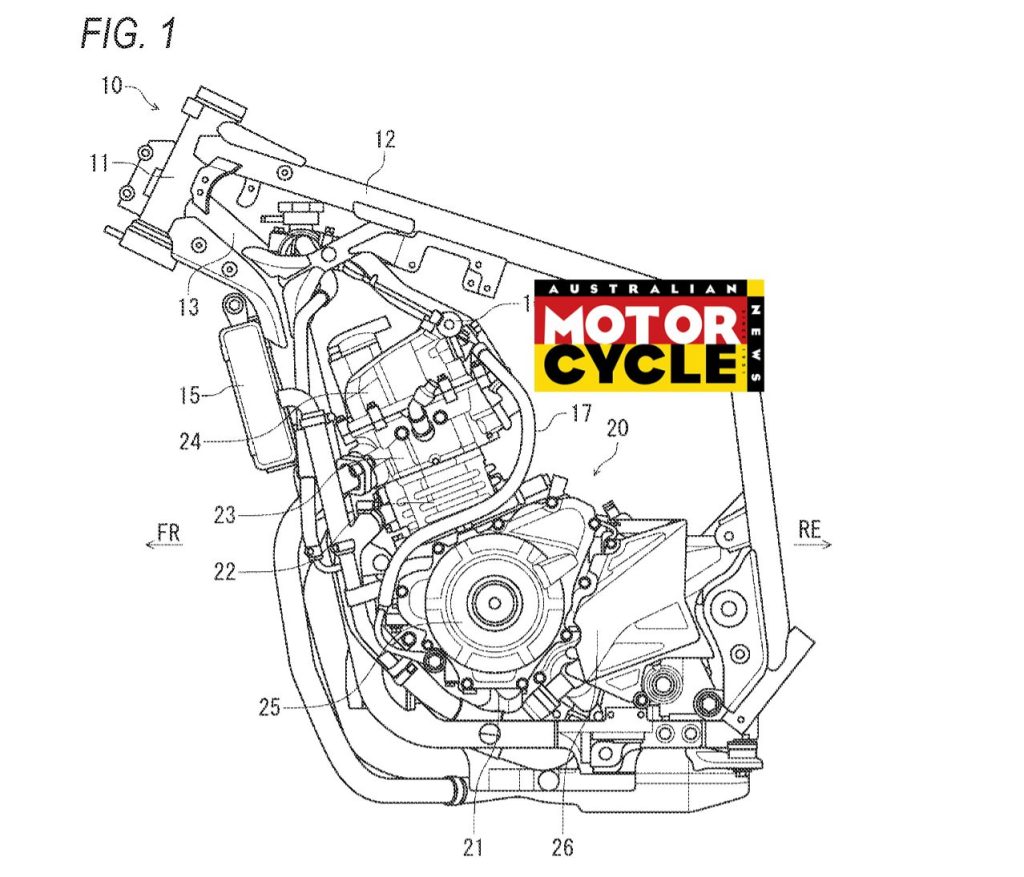

Suzuki’s version of the idea is designed around a single overhead camshaft engine, and in the patent illustrations the bottom end and cylinders appear to be from the GW250 parallel twin. The single camshaft operates both the intake and exhaust valves via roller rockers and Y-shaped arms that allow each cam lobe to open two valves.

The design is fairly conventional, with two intake cam lobes for each cylinder – one mild, one more extreme. The rocker that operates the intake valves is in two parts, with a roller on each of the intake cam lobes. At low revs, the milder cam lobe is used and the two halves of the intake valve rocker are disconnected. At higher rpm, oil pressure is used to insert a pin between the two sections of the intake valve rocker, locking them together so the wilder cam lobe is used.

It’s essentially the same idea used on several other VVT engines, and the patent application itself is focus on some subtleties of the locking pin design aimed at making it compact and reducing wear.

What could the engine be used in? Suzuki has previously used the non-VVT version of this parallel twin in various models including the GW250 Inazuma and the V-Strom 250 as well as the GSX250R. If VVT can give it a new lease of life under ever-tougher emissions rules, it could be adopted by a similarly broad range of small-capacity machines.

WORDS: BEN PURVIS