Somehow it’s appropriate that Pere Tarragó, creator of the finest and most intricate miniaturised motorcycles made in Europe, should live in Barcelona. For this is the continental capital of motorcycles – no matter what they may think in Paris or Rome – where more people ride powered two-wheelers through its streets each day than anywhere else in the European Union.

The Catalan capital was also the crucible in which the Spanish motorcycle industry flourished during the regime of General Franco, but then died away with his passing in 1975, in the face of competition from Japan. So it’s ironic that today the only Bultaco and Montesa motorcycles still made there are the exquisite 1:5 scale models created by Tarragó in the workshop attached to his home in the Barcelona suburb of Molins de Rei, just a long stone’s throw from MotoGP promotor Dorna’s HQ at Sant Just Desvern.

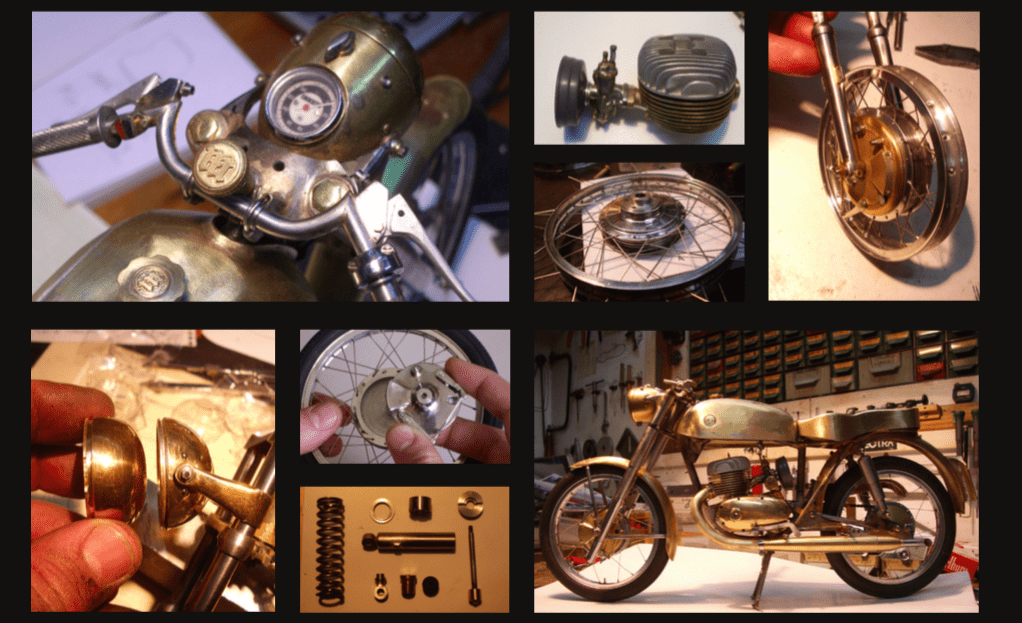

The models are breathtakingly executed, finely detailed and faithfully accurate works of two-wheeled art. Some are entirely hand-crafted one-offs built to special order and cost anywhere from €12,000, or A$18,500, upwards. Others are hand-assembled series production models that retail for considerably less than that.

So far the best sellers have been the Montesa Impala 250 and its essentially identical 125 sister – 72 examples of these have been sold to date and you can have your own for €2,050, or about A$3175. Meanwhile, 18 copies of the Bultaco Metralla 250 have found customers so far. This model goes for €2500, or A$3850. All prices are plus tax. If your pocket doesn’t run to that, but you’re still after a display item to remind you of Spain’s glorious two-wheeled heritage, then the engine for either bike can be yours for €250 (around A$380), or the fuel tank for €150 ($230), each mounted in a special display case. The complete bikes come well presented in a wooden box.

Pere Tarragó, 61, is one of those fortunate men who’s made his hobby his livelihood – a fact which allows him to shrug off the long eight to ten-hour days he spends seated at his workbench hand-crafting the more than 500 individual components comprising each one of his creations, then assembling them into a complete finished model which is visually identical to the original motorcycle. Formerly an electronics engineer, he previously owned a hi-fi audio equipment store in downtown Barcelona, selling Bang & Olufsen products, among others. In 2007, just on the cusp of the economic downturn, he sold the business to switch careers, and become a full time model builder, in between exploring Europe together with his wife on the Harley-Davidson Heritage Softail Classic that shares his garage with a Moto Beta 250 trailbike. That turned out to be an astute decision – but why did he do it?

“I’d been making models ever since I was a kid – first with Meccano, then small scale copies first of cars, then ships, aircraft, and finally motorcycles,” says Pere. “I made my first two-wheeled model in 1995, which was the 1972 Bultaco Metralla in 1:6 scale, but to do so I had to make each link of the chain by hand, which was very time-consuming, and rather boring. Still, it was displayed at the big Auto Retro show here in Barcelona, and the response was quite overwhelming – many people asked me to make one for them, too, without knowing a price. But then a company in Japan started selling chains in 1:5 scale – so then I had to completely remake the Bultaco in a smaller scale to suit that! I considered the larger one as a prototype, and I learnt a lot from making it, which still stands me in good stead today. Next I built a Montesa Brio in 1996, and three years later an Ossa 150, followed by an MV Agusta 175 Squalo, which was my first four-stroke.

“By then I began to think about doing it as a business – before, all this had just been a spare time hobby. Then in 2005 I finished building a Montesa Impala, which I again displayed at Auto Retro, and had many requests to make copies. I thought – well, I enjoy doing this, and it means I can work at home without having to commute to the centre of Barcelona each day, or paying a heavy rent to run the store, with all the worry of employing people. So I sold the hi-fi business – just at the right time! – and all I’ve done since then is make models. Every time I do a new one I learn something more; you never stop devising new techniques to get greater authenticity.”

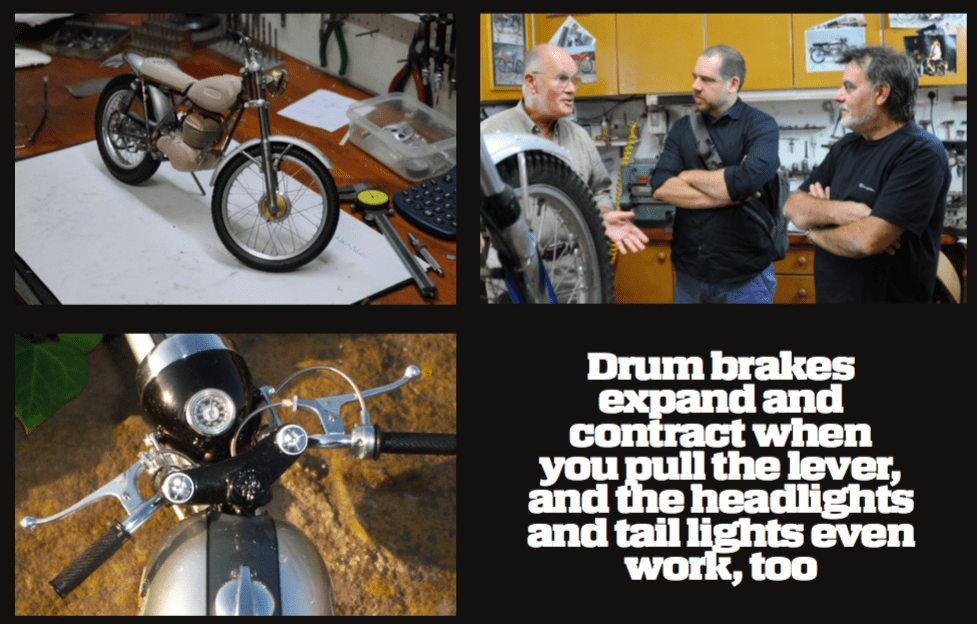

And that’s the key word for Tarragó’s creations, because his models are acclaimed for their attention to detail, as well as their functionality. While the engines won’t actually fire up and run, that’s about the only thing that doesn’t work just like the five times larger component it replicates.

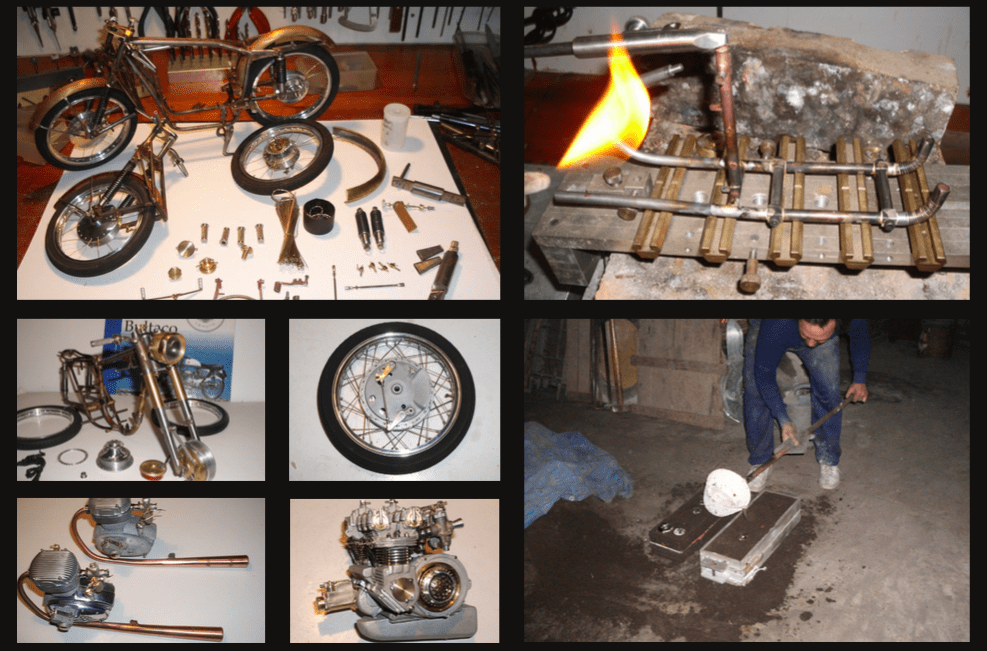

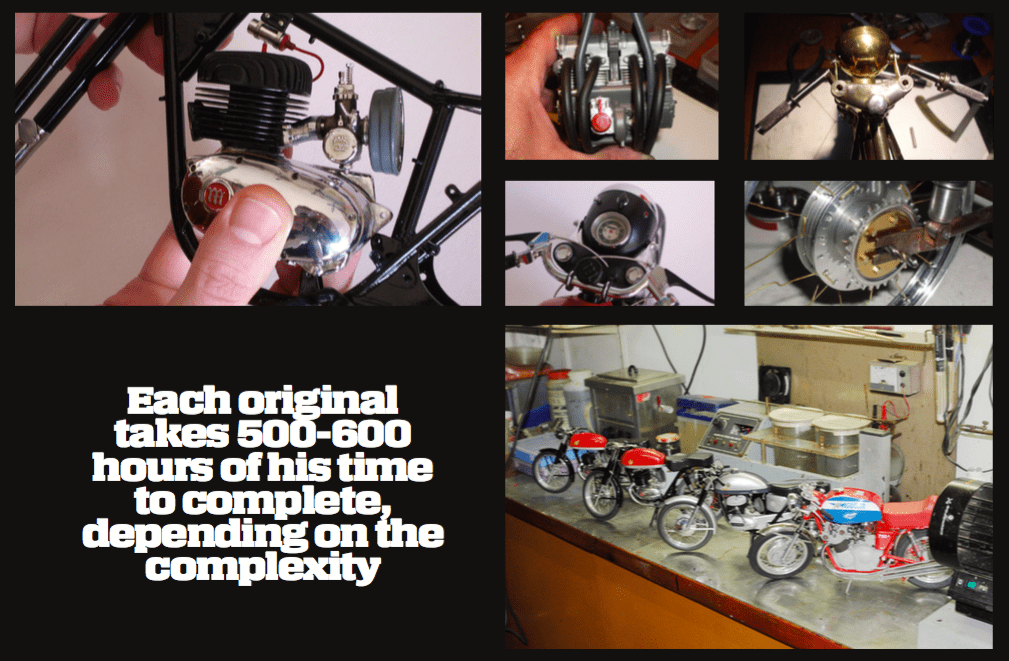

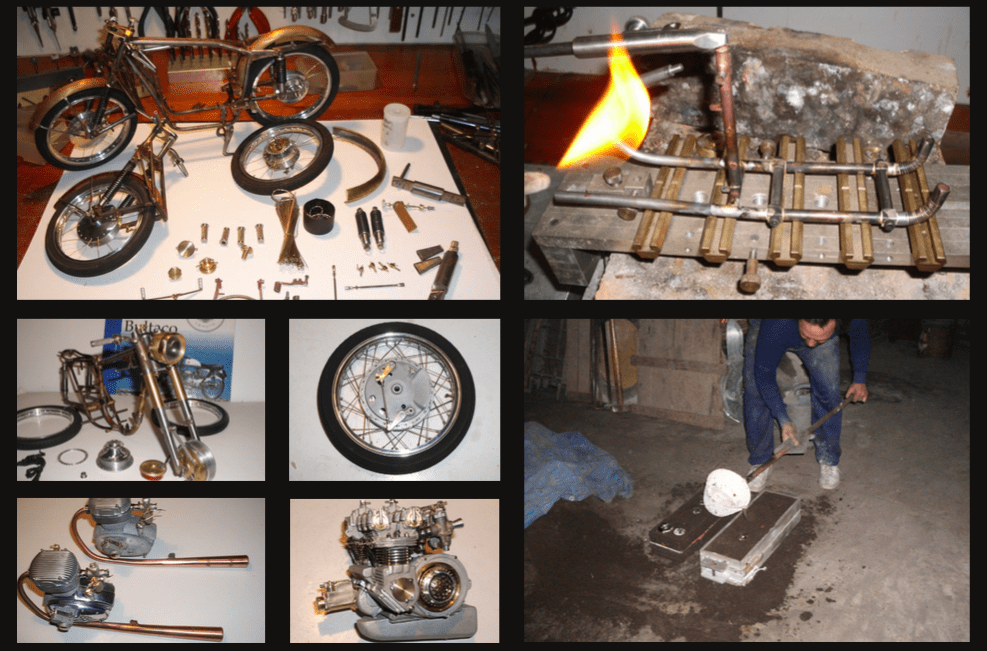

So, yes, the drive shaft on the vintage BMW R32 he made in 2009 does actually rotate, though it’s the rear wheel that drives it, not the engine. Same goes for the chains on other bikes, while the kickstarts on all his roadbike models kick down and then spring back up again, same as the gearlevers. The forks and shocks all compress and rebound just like the originals, too – although there’s no oil inside for damping! The rear shocks are all three-way adjustable for spring preload, while the brake shoes of his intricately replicated drum brakes expand and contract when you pull the lever, and the headlights and taillights even work, too, thanks to an artfully concealed tiny lithium battery. These are true fifth-size replicas of the original motorcycles, manufactured in authentic materials like steel, brass, lead or aluminium, not plastic. And in creating them, Pere employs many of the techniques used to make the originals, including sandcasting and lost wax casting techniques, machining components on his high precision lathe, and even using carbon fibre, though not to save weight, but to obtain complex shapes more easily.

How he does it

After choosing the next new model to make, Pere first of all must obtain an example of the original motorcycle to replicate. That’s one reason why, until now, most of the bikes he’s built have been Spanish models, original examples of which are plentifully available locally. Besides the Metralla, Brio and Impala, the different dozen-plus miniatures he’s made to date also include the Derbi 50c RAN (Replica Angel Nieto) customer GP racer, Bultaco Sherpa T trials bike, and streetbikes like the Ossa 150 and Spanish-made Moto Guzzi 65. Next model to come is a 250cc Ossa MAR (Mick Andrews Replica) trials bike, and there on the workbench at the time of my visit was an original example which Pere was in the process of painstakingly measuring up and photographing in minute detail.

“I take around 600-800 photos of each bike, and produce a detailed scale drawing by hand of each component I must make, with all relevant measurements which I can then reduce to one-fifth scale,” he says. “I also study the handbook and service manual, if these exist, and then I start work to build the model. Whether I’m making a one-off example for a customer, or a series production prototype, the procedure is the same.”

Each original takes 500-600 hours of his time to complete, depending on the complexity, with each day’s work carefully noted down in his logbook for each creation. The longest so far has been the 618 hours he spent creating a perfect small-scale replica of the 250cc four-cylinder Benelli with which Tarquinio Provini won the 1964 Spanish GP on the nearby Montjuic Park circuit, a bike which is owned by local collector Joaquin Folch – whose Titan paint company even provided the right colour of paint to clothe the model in!

“But this was the most complicated model I ever did,” Pere notes,“ because of the intricacy of the engine and the four carburettors and so on.” Even the MV Agusta 750S streetbike he also made, of which he’s built three examples so far, wasn’t as time-consuming, taking ‘just’ 550 hours.

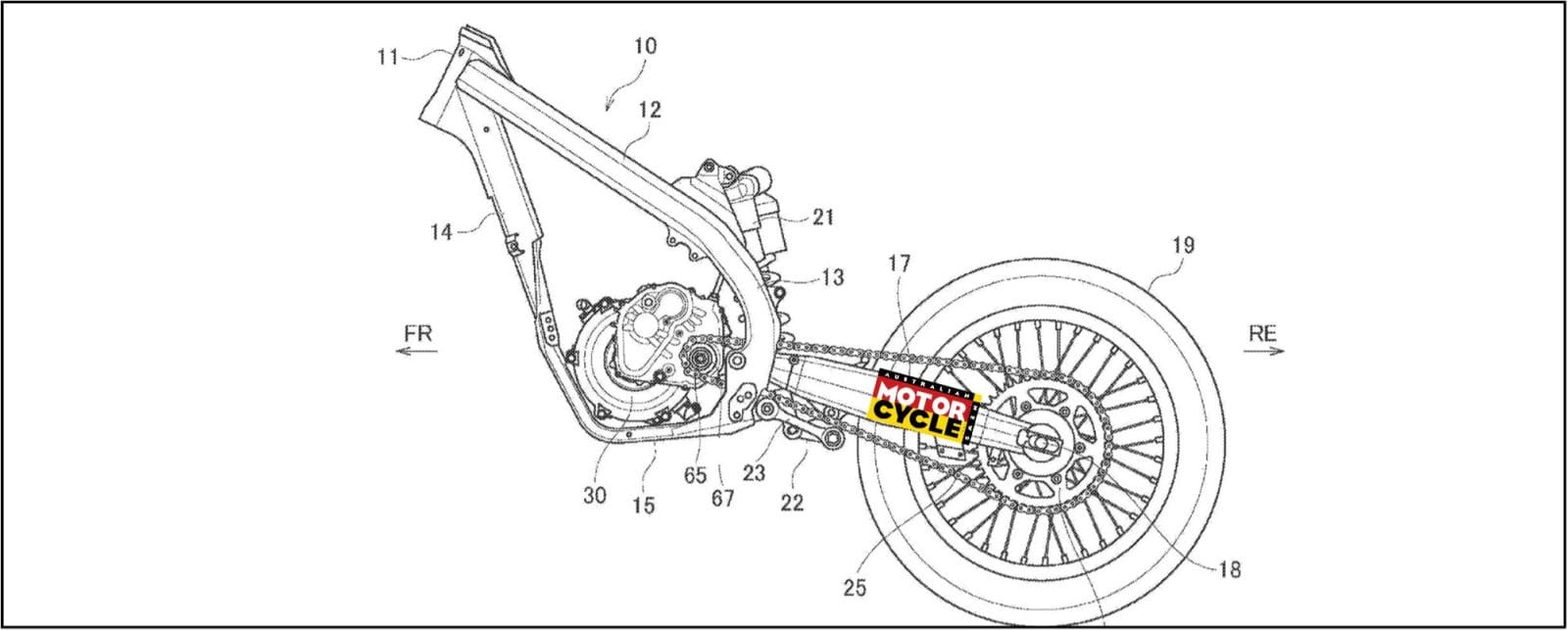

Having drawn up all the components he needs to make, Tarrago always starts by building the chassis with silver-welded steel tubing. For the production frames he makes a jig of the original, and replicates the frame in brass. This is less-time consuming to work with and helps keep the price down. Next come the wheels, and all his models so far have had drum brakes, which he first creates by hand on the lathe, then sandcasts for production.

“I was fortunate to find a jewellery factory not far from here which can produce small volume components very affordably, and with great accuracy,” says Pere. “Without them, it wouldn’t be feasible to produce the models at an affordable price.”

The wheel rims used to be milled from solid blocks of aluminium on his lathe, which meant they could only be smooth, not ridged as on a competition alloy rim, but for the Benelli and other racers since then he’s been able to source these from the jewellery factory, leaving him the fastidious task of boring holes in them, then lacing them to the drum using some of the 1.5 million wheel wires he had to buy to make them affordable. “Lacing up the wheels is the worst part of building a bike,” says Pere. “It’s very monotonous!”

Next comes the fabrication by hand of the various other chassis components, based on his detailed drawings: suspension, controls, instruments etc. On the production models these are re-created in greater volume in the jewellery factory, either by casting or CNC-machining using a program compiled by Pere’s son Jordi, 35. He also takes care of making the tyres, which are formed in a special kind of liquid rubber that can be poured into a two-piece mould which has been CNC-machined to produce the shape, then the tread pattern spark-eroded onto the wall of the mould, again using a computer program.

Finally, it’s the turn of the engine, and here Pere either carves it out of solid [what?] on his precision lathe, even down to building up the cylinder finning by making each individual fin, then glueing them to the cylinder. If it’s too intricate a design to do this, he makes a plastic model and then takes a mould off it, which then allows him to replicate it in cast aluminium. This may even happen on a one-off model, but it’s the approved technique for building all the production versions.

Next comes the fuel tank and bodywork, and here Pere will painstakingly hammer out the metal shapes of the tank and mudguards in 8mm thick brass plate, before taking a mould off the finished product for his production bikes, and getting Jordi to paint them with a special two-pack material which has been computer mixed to obtain exactly the right colour. And now comes the time to assemble everything, which Pere always does himself. Although the volume production models use parts made in a factory, each of them is hand assembled, so the handmade tag still definitely applies.

Okay, Pere – now for the crunch question: which one is your favourite out of the 20 or so different models you’ve done so far? “All of them!” comes the answer. “I enjoy very much the process of making each one, so while of course I’m satisfied with the end product, it’s all the many things I had to do to get there that I get pleasure and satisfaction from. And from learning all along the way – you never stop doing that. I especially got a lot of pleasure from making the MV 750S fuel tank, which is a very complex shape that’s hard to replicate. In the end, I had to make a clay model, then use that as a basis to form a metal sheet over it to produce the correct form. Each of the three versions I’ve made so far was built as a one-off, but now we’re going to make a production example as the next new model in our range, after which we’ll do the bike I’ve been waiting to produce for many years – a Featherbed-framed Manx Norton! I think this is the most classically beautiful racing motorcycle yet built, so while the engine will present quite a challenge with all the finning and the beautiful cambox, I’m looking forward to it. I hope finally making a model of a British motorcycle will help me to find many customers in English-speaking countries!”

It might do so, Pere, it very well might!

Tempted?

For information on how to purchase your very own Tarragó model visit www.motoscalatarrago.com.

By ALAN CATHCART

PHOTOGRAPHY JIM SCAYSBROOK