1.Wavy discs: gimmick or gotta have?

Wavy (or petal) disc designs have been a common sight on roadbikes for several years, firstly as aftermarket upgrades, but more recently as original equipment. So what’s the deal? Are they better than regular circular discs?

For road use, the theory is that a wavy disc can give you all the performance of a circular disc of equivalent diameter and thickness, but with significantly reduced weight.

There’s no doubting the potential benefits of lower wheel weight – lighter steering, faster acceleration, improved suspension performance – but the fact is, heavily stylised petal-shaped rotor designs just don’t match a quality full-circle disc of the same size in terms of pure braking performance.

Don’t believe me? Just take a look on the grid at any top-level road racing series. Chances are you won’t see many, if any, wavy discs on the bikes, and you certainly won’t see them on a factory MotoGP or WSBK machine. Which in itself should be proof enough.

That’s not to say wavy discs don’t have their place. Beside the fact they look pretty cool, in the world of dirtbikes – where they originated – they can provide an advantage, even in braking performance. This is because the factor often inhibiting braking force off-road is all the mud, crud and crap that covers the disc. The shape of a wave disc can assist greatly in making it the ultimate shit-shifter, clearing the braking surface so the pads can bite.

2. Will monobloc calipers help me do better monos around the block?

Not likely, chump.

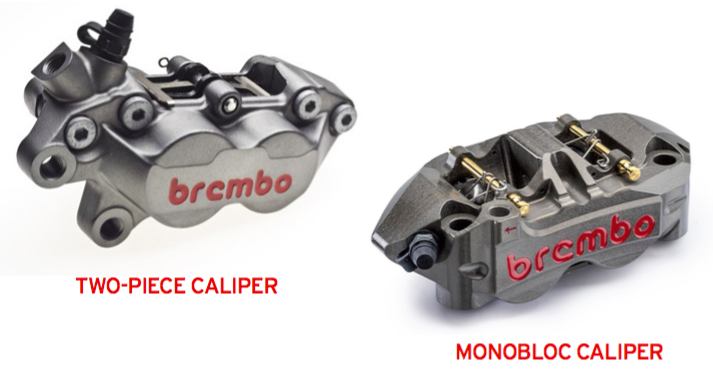

A monobloc is simply a brake caliper that has a body constructed from a single piece of aluminium, as opposed to a two-piece caliper, which is bolted together. So which is better?

Contrary to popular belief, a monobloc caliper is not more rigid than a two-piece caliper of equal quality and proportions. The reason being that the bolts holding the split caliper together are less prone to bend or stretch than the aluminium bridges of the monobloc caliper. In technical terms, that’s because steel has a modulus of elasticity around three times greater than that of aluminium.

The performance benefit in the monobloc’s design is purely in its reduced weight, which of course is unsprung weight and therefore also a potential handling advantage.

Perhaps more surprisingly, considering a monobloc caliper’s perceived premium-part status, a secondary benefit is lower manufacturing costs. The monobloc’s design requires fewer parts and processes in its production.

3. Is radial mounting on my Gixxer the same as mounting radials on my Falcon?

Um… no.

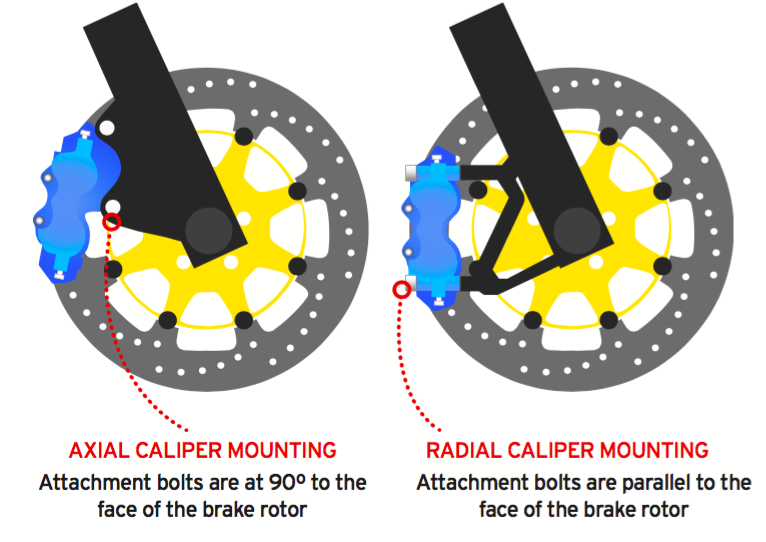

Brake calipers are either mounted axially, with the bolts at 90o to the disc’s braking surface – or radially, with the bolts in line with the disc.

Radial mounting increases rigidity, and also allows wider caliper compatibility across different models of bike due to one caliper fitting various disc diameters.

This is extremely useful for racing applications, where it’s often preferred to fit smaller discs for wet conditions or race circuits requiring less heavy braking. Just increase or decrease the mounting spacer thickness to suit the disc size.

4. Righto, so is that the same as the radical master cylinder on my Gixxer?

It’s called a ‘radial’ master cylinder, mate.

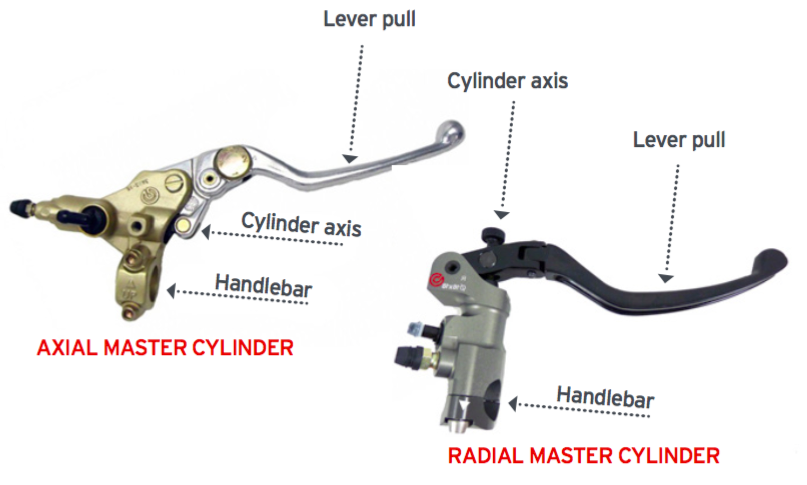

Just like brake calipers, master cylinders also come in axial and radial designs. This refers to the orientation of the cylinder and the piston that pumps hydraulic fluid through the brake lines and into the calipers.

An axial master cylinder has a piston that travels in line with the handlebar, at right-angles to the brake lever’s direction of travel. With a radial master cylinder, the piston moves parallel to the direction of lever travel.

As with radial calipers, the advantage comes with the design’s increased rigidity. This equates to more braking consistency and improved feel.

5. What’s a floater?

Let’s hope you’re asking about floating discs here, and not some mystery semi-submersible spotted lurking in the kiddie’s pool.

Floating discs are identifiable by their two-piece construction. Generally, they will have an inner disc carrier made of aluminium, around which the steel braking rotor is mounted using rivets, sometimes referred to as buttons. These buttons allow the braking rotor to move, or ‘float’ in relation to the wheel, as opposed to being solidly mounted.

The amount of float will differ depending on the application. Roadbikes fitted with floating discs as standard equipment will have relatively little float to prevent noise and reduce wear. Road racing bikes with high-performance track-specific discs often have a great deal of float.

On some racing discs the amount of lateral float can be adjusted using a combination of shims and spring washers on removable buttons. Vertical float can also be adjusted to accommodate temperature-related disc growth or shrinkage, using different diameter buttons.

The benefits of floating discs are threefold: they provide more accurate and consistent alignment between the brake rotor and the brake caliper than a solidly mounted disc does; they allow the rotor to grow and contract throughout extreme heat cycles with less risk of distortion; and, depending on the design, they can also run cooler, resisting the distortion associated with overheated discs.

WORDS Paul Young Photography AMCN ARCHIVES