After removing the front fork assembly last time and discovering that the fork tubes are indeed bent we figured on getting some expert help to find out the easiest and cheapest way to have the problem rectified. Thankfully we managed to bring in the big guns – Terry Hay and his crew of suspension experts at Shock Treatment, in Wallacia in Sydney’s western suburbs. When we spoke to Terry on the phone, he floated the option of straightening the bent tubes on a special jig that he has in the workshop, thereby avoiding the cost of replacing them. We were fascinated to see how this was possible and if it could be successful. Check it out…

Start here

1 Firstly, the fork tubes need to be removed from the legs. As they are not mechanically attached on the Tele lever system they should slip straight out, but one tube is so bent it has to be heated with the gun and worked hard to extract it from the fork leg

2 Once the tubes are separated we can put them on a steel bench to measure the bend – 15mm one side and 8mm the other. It is a significant bend but luckily the steel has not creased or split so Terry is confident they can be straightened

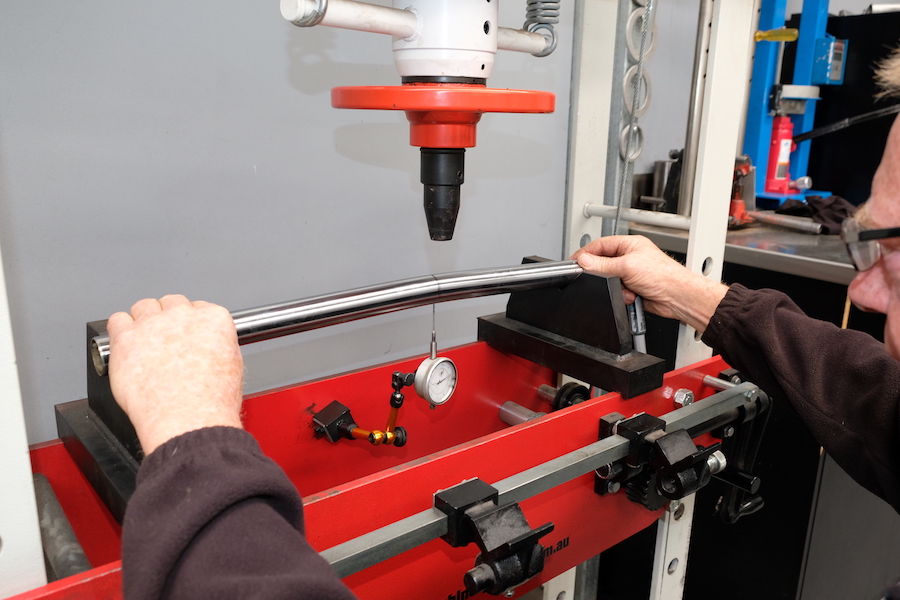

3 Terry sets up the worst tube in the jig for the press machine, marking the lateral centre and then the highest point of the bend. The dial caliper gauge measures exactly how much the tube is out of round

4 An adapter is utilised to spread the force being applied to the fork tube from the press machine as Terry carefully watches the gauge to measure how much movement he is generating

5 Terry explained that the steel has an elastic element to it that needs to be measured to allow an accurate correction. This tube deflected back 7mm after adjustment so Terry moved the tube by 9mm each time to start, meaning an incremental straightening of around 2mm every time he applied the pressure

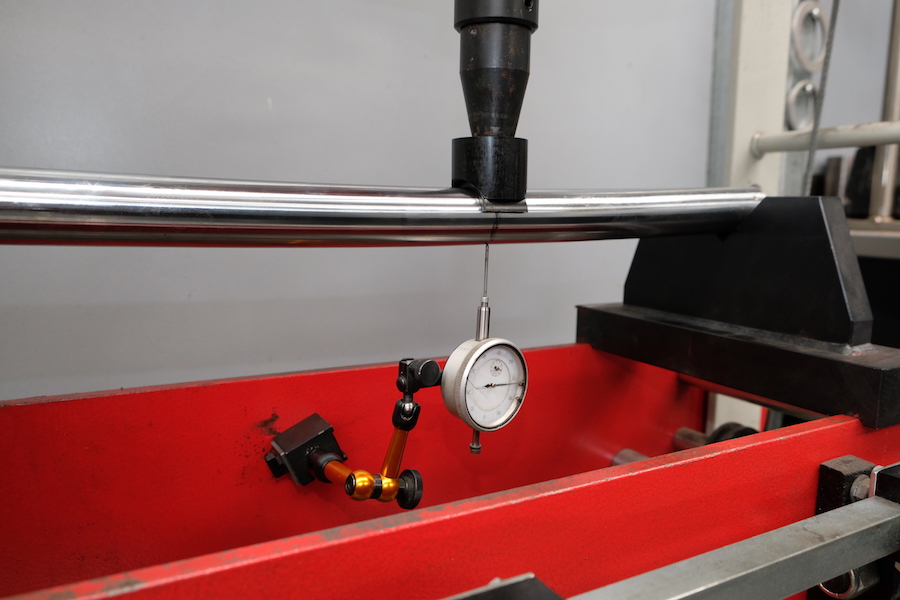

6 It is a slow and careful process with Terry turning the tube each time to accurately measure the progress and make any necessary adjustments

7 As the tube gets closer to being straight the amount of movement is reduced to eventually get to a point where tolerance is 0.3mm from dead straight or less. Impressive

8 Once both fork tubes are completed the new fork and dust seals can be fitted

9 Fresh fork oil is added to the forks

10 With the forks now reassembled we can take them back to the shed and get back to work

Terry, hey?

Terry’s facility at Wallacia is purpose built for suspension and mechanical work and his staff are really professional and well trained. Terry personifies the old school philosophy, a process-based, mechanical approach to problem solving. He works patiently and methodically until he gets the right result – a rare skill these days. For all suspension and general workshop or engineering needs we highly recommend Shock Treatment. Find it at 639 Greendale Road, Wallacia, NSW. (02) 4773 9115

Words & photography Tim Munro