Hi there, I’m a motorcycle designer. It sounds like a great job, right? And pretty simple really. There’s your blank piece of paper, there’s your damned crayons, so you’ll have something over to us by five, right? Riiight??

Well… let’s just say designing the perfect two-wheeled machine has a comprehensive list of challenges that isn’t getting any shorter. Aside from the normal stresses any small business faces – bills, overheads and keeping the lights on during quiet times – consider delivering not only original ideas predicting future design trends and accounting for the varied tastes of your target market, but also practical, buildable work.

You’ll have to meet the corporate requirements of the brief, address existing design language constraints (a Beemer’s gotta look like a Beemer, son) and last but not least, deliver something that the customer actually likes.

Now feel that sting when the customer says of your perfect first draft: “I don’t like it.” But doesn’t tell you why. Feel your smile turn upside down when it’s pointed out how difficult/expensive/impossible your slick new styling feature will be to produce. A sense of humour comes in handy here.

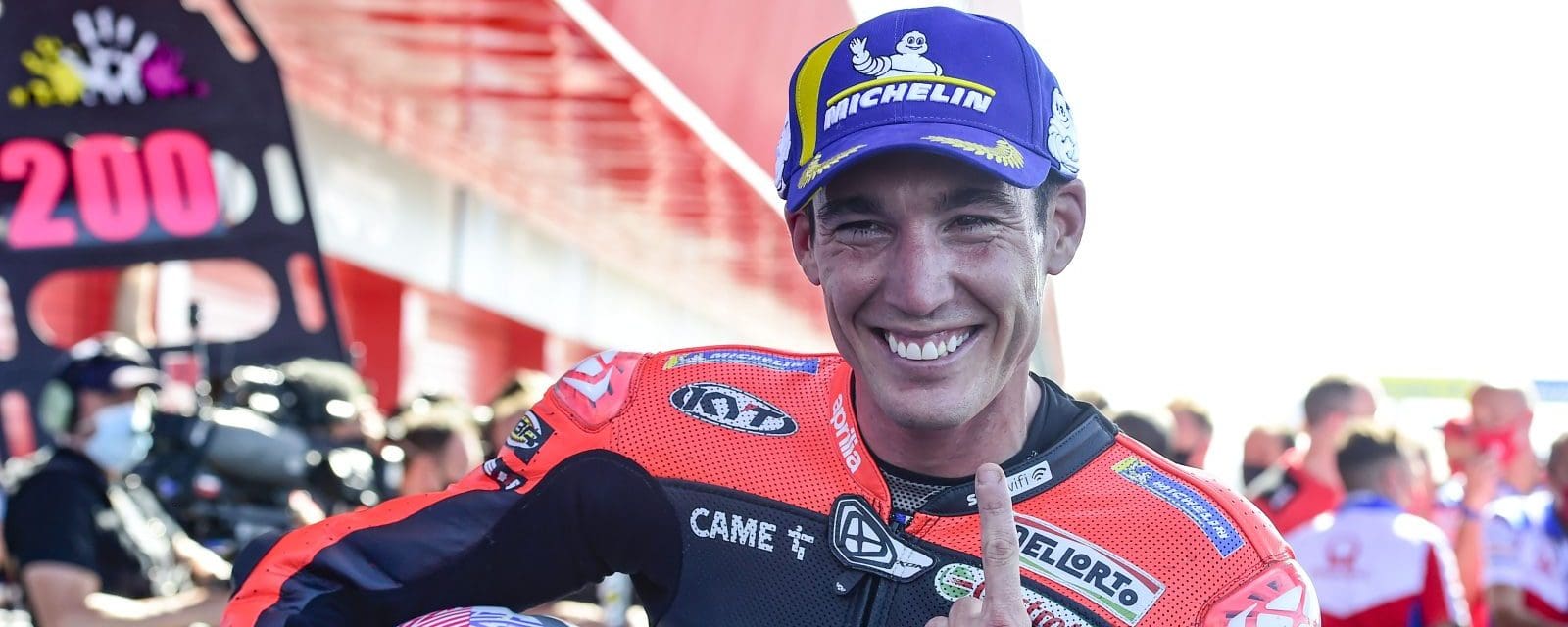

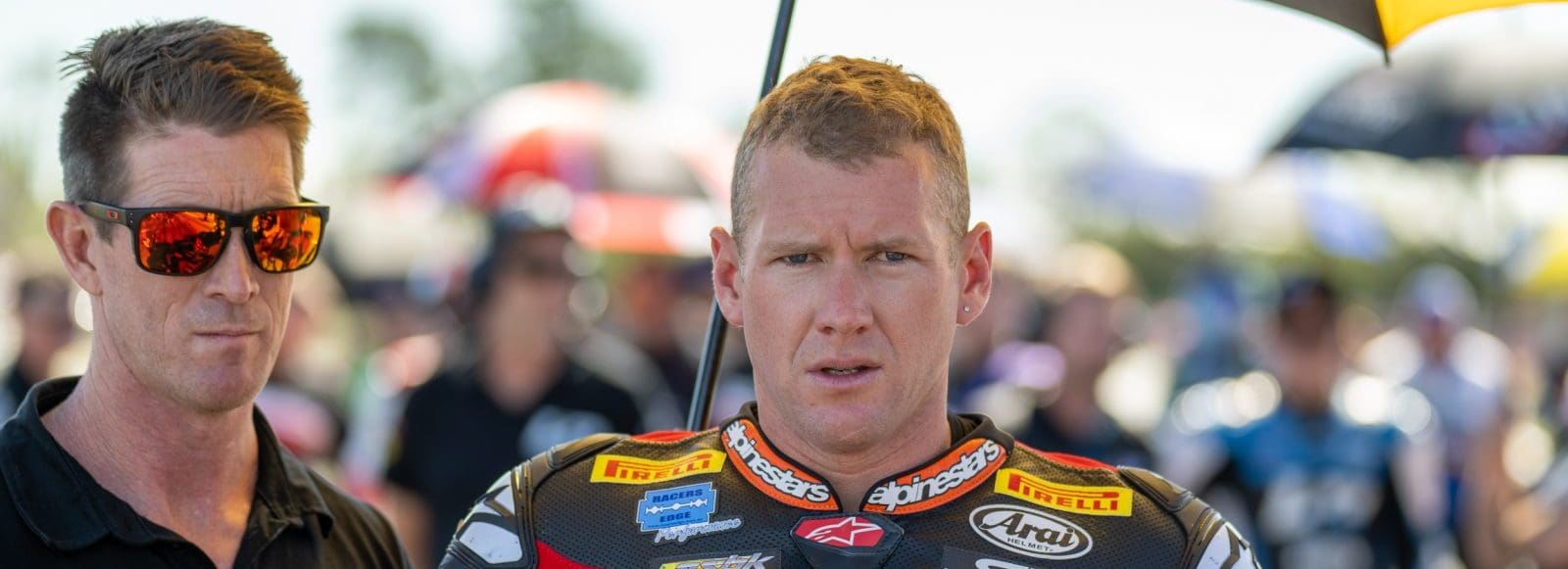

But I’m not complaining. Oh no. I’ve always felt blessed to be given the opportunity to do this job. And I’ve felt the same way since my first major bike design, the Traverston V-Rex (pictured), went into production with Christian Travert, in 2007. From day one, he saw what I saw, and didn’t change a thing – the bane of any designer (just ask Jorn Utzon!) When I got to ride one a few years back on the Gold Coast, it was one of the greatest days of my life.

Viewing prototypes you’ve designed is just the best. Seeing an idea that was in my head now a solid reality always leaves me dumbfounded by how clever the people I have the pleasure of working with are. CAD guys, engineers, fabricators and the other professionals engaged in vehicle production are my heroes.

But what’s in store for the future? Recent events have definitely shaken things up at a fundamental level, before we can even get designing. Thank goodness there are smart people working hard to make compliance possible with some of the trickiest emission requirements ever spawned in Euro 5, even Euro 6.

As usual, packaging will dictate. Before we start to design, questions must now be asked such as what powerplant will we be able to legally use, and in which markets? Shall we still go with an internal combustion engine (ICE), an electric drivetrain or even both in the form of a hybrid platform?

For a Euro 5/6 compliant ICE, there’ll probably be more electronics, bigger cats, perhaps even changes to cooling systems, all things to be worked out before an HB pencil gets lifted in anger at my desk.

The real trick will be the two-wheeled hybrid. I tried to show it could be done with the Caf-E Hybrid back in 2009, where I found the existing Prius battery pack and a parallel-twin ICE could fit inside the wheelbase of a full-sized motorcycle. Then Yamaha did the heavy lifting and built its HV-X as a proof-of-concept.

A straight ’leccy bike is somewhat simpler. I’ve designed several over the last few years, and while it’s been great to experience the freedom afforded by the lack of an ICE, in many cases, this freedom has been swapped for some new headaches.

For one, car companies are now struggling to replace the redundant but brand significant grille/radiator opening in their electric cars, and it’s a similar story with an electric bike’s lack of ‘fuel tank.’ The petrol tank has defined many a bike design and has been with us for about 100 years, so it’s not going to just go away quietly in the mind of the customer.

But what to put there instead? Handy helmet holder? Esky? Space for a really long extension cord? Oh wait I’ve just got it – lockable magazine storage! Read your favourite issues of AMCN whilst waiting for your electro-beast to recharge at the charging station! Stay informed as it charges and charges and charges

and charges and charges…

At least that’s one motorcycle design problem solved!