IN THE MOVIE Jurassic Park, a billionaire with a passion for dinosaurs employs a team of genetic scientists to create a wildlife park on a tropical island and fill it with cloned Tyrannosaurus Rex, Velociraptor and Brachiosaurus.

But what if your passion is old motorcycles, and there are no survivors of the most important models that your country ever made? You can’t clone them, but if you’re an engineer with enough skill and determination then anything is possible.

If you don’t believe us, just look at what Pavel Malanik has brought back from extinction using only the old lathe and a milling machine that he has in his home workshop.

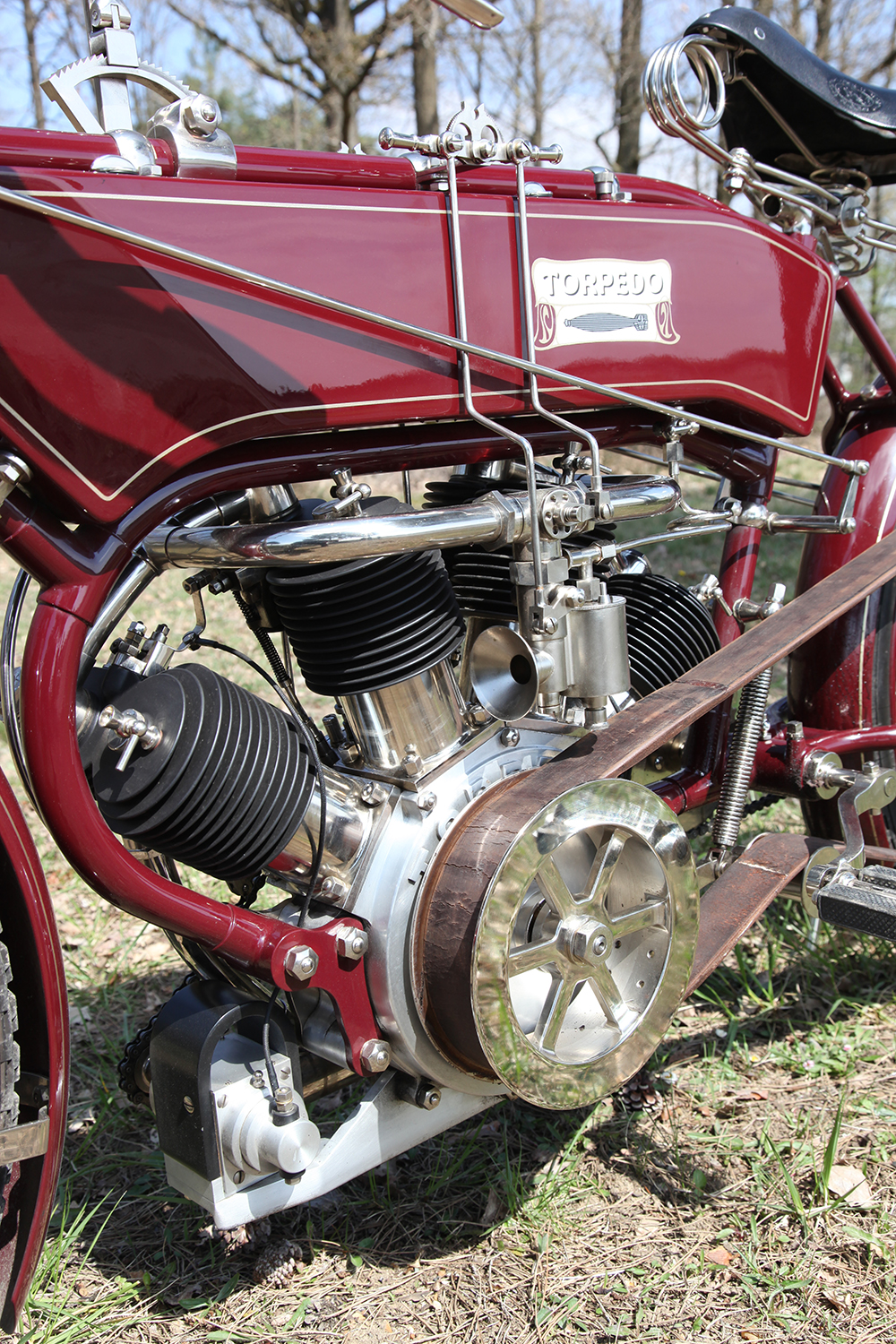

Only one semi-radial in-line four-cylinder Torpedo racer was ever built, but thanks to Pavel, who spent about 2500 hours in his workshop creating his replica, we can hear it roar into life again.

As a proud Czech, Pavel well knows the history of his country and the motorcycles that were made there. In 1902 Frantisek Trojan owned a small business specialising in nickel plating and foundry work in the centre of Kolin, a small town 60km east of Prague. He rode a Slavia in a 200km race that passed the Laurin & Klement (Škoda) factory and was so impressed he decided to start selling them. However, two years later he was ready to go into production with a range of motorcycles of his own design, under the Torpedo brand. These were all 330cc singles with automatic inlet valves, forward-mounted low tension magnetos and flat-belt drive to the rear wheel.

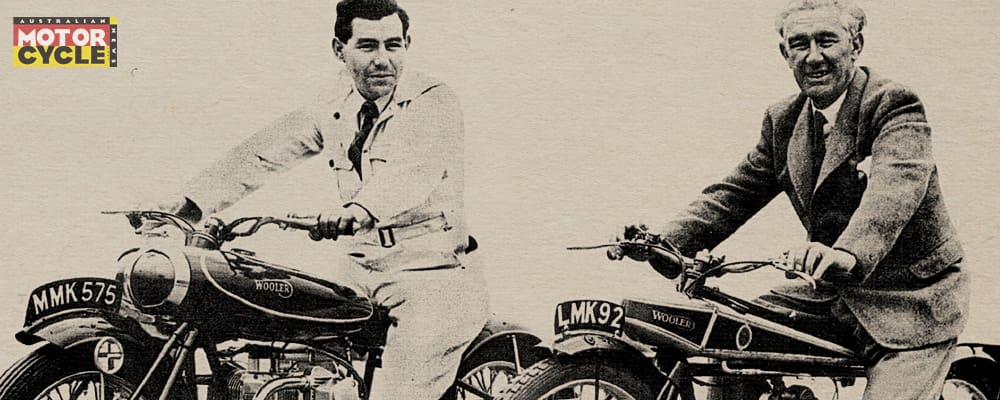

Steel maker Alois Nagl joined Trojan as a partner and injected money into the business. Trojan & Nagl Torpedo motorcycles were exhibited in Vienna and Prague in 1905, and were exported to Austria, Spain and even Brazil. These featured 3 or 3.5hp singles, and 4 or 7hp twins.

The workshop doubled in size in 1907 when the partners bought the terraced house next door and knocked through the walls. These were the boom years for Trojan, and in 1909 the partners displayed what is probably the most interesting Czech motorcycle ever made – the Torpedo radial-four racer.

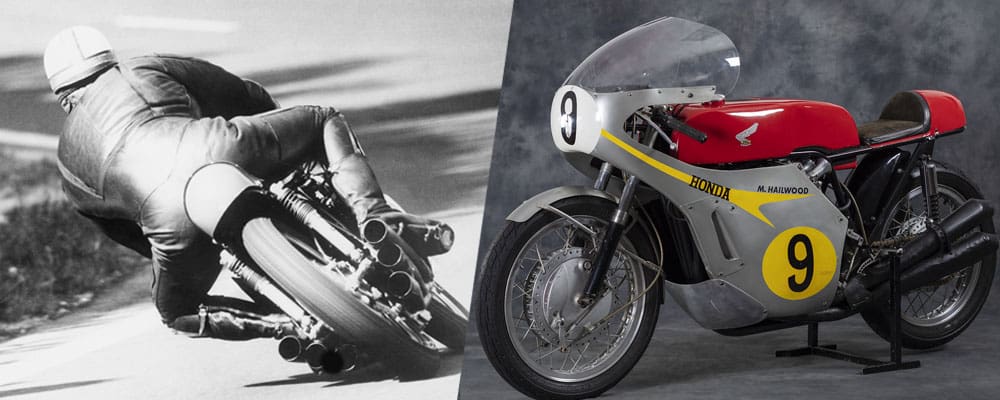

With a 73mm bore and 100mm stroke, the engine had a capacity of 1640cc and was rated (for tax purposes) as 10-12hp at 2200rpm. Top speed was over 120km/h, which made the Trojan the fastest Czech motorcycle of the time.

Trojan and Nagl even went into aircraft production and by 1914 were also making cars, but they stretched themselves too far and the company struggled to survive into the 1920s.

Unfortunately for Pavel, the original Torpedo racer has disappeared and only a single photograph remains. There is also a line drawing of the engine, so he used these as the basis for his creation.

Pavel used measurements of known components like the wheel rims and flywheels to come up with dimensions of other parts, and produced scale drawings.

The process of making an engine crankcase and cylinder barrels is quite involved. Having patterns made to cast the crankcase halves would have been too expensive, so Pavel instead machined the crankcase from a single block of aluminium using his lathe, a milling machine and a rotary table so that the angles between the cylinders would be perfect.

He bored right through the aluminium block so that the mainshaft bearings would be in line, roughly machined the main external shape, then cut the block in half along the vertical line. He then milled out the timing chest and bored the holes for the cam wheel shafts, tappet blocks and engine bolts.

Pavel could see that the four connecting rods had to be on a common crankpin and, because of the position of the barrels in the photograph, that they were placed side-by-side and not in two pairs of ‘blade-and-fork’ as used on a Harley-Davidson V-twin. Then he made the conrods, the big-end and flywheels, the cams and followers… This is not a man who would spend his evenings on the sofa in front of the television.

The four cylinder barrels with their square base flanges were machined from steel. Each automatic inlet valve and side exhaust is in a pocket on the side of the barrel, so Pavel milled the fins off one side before welding the two components together and pressing in the cast iron cylinder liners.

Pavel fabricated the frame lugs and bent the frame tubes to shape before brazing them together. He also made the forks and tank, plus the two-speed hub with its planetary gears (a bigger version of the type still used today on bicycles), two low-tension magnetos and the single forward-facing carburettor.

The radial four uses a ‘make and break’ ignition system.

The low-tension magnetos generate a current, but this voltage is not enough to create a spark that will jump across the gap of a spark plug screwed into the combustion chamber of a high-compression engine.

Instead, there is a pair of breaker points inside the combustion chamber. One point is connected by an insulated wire to the induction coil in the magneto, while the other point is earthed and is actuated by a pushrod that, when it strikes the breaker arm at the top of the stroke, separates the breaker points and produces the spark.

A low-tension ignition system limits engine revs to about 2000rpm, and also limits the compression ratio.

Pavel could have built a much more powerful engine simply by using high-tension Simms-Bosch magnetos that were readily available in 1909 – but he wanted his replica to be a faithful copy of the original.

Because he didn’t use CNC machinery, there are no computer programs so he can’t simply hit a button and make another radial four engine. But that doesn’t mean Pavel is afraid to use the maximum performance available from his Czech masterpiece.

We caught up with him at Montlhéry, south of Paris, for the Vintage Revival, where he ratcheted open the throttle of the racing Torpedo and really showed what it was capable of.

We’re not able to hear an actual Tyrannosaurus Rex roar, but thanks to Pavel Malanik we can all enjoy the unique sound of an incredibly rare semi-radial four on song.