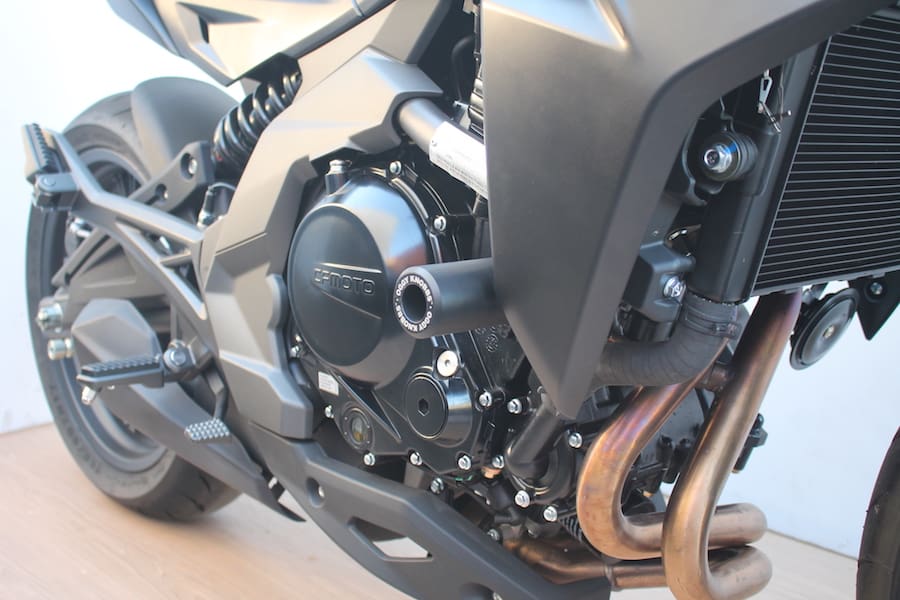

Oggy Knobbs is one of the best-known crash protection brands in Australia and a true blue home grown product, so it seemed a good choice for our new CFMoto. Just one problem – the existing kit, designed with the 2014 650NK in mind, didn’t fit the new model.

Luckily, there was a solution. The guys who make Oggy Knobbs are located across the bay in Williamstown, and they offered to use our 650NK as a test mule to design a suitable kit. It also gave us a chance to check out a bit of an endangered species in our country – a manufacturing business.

Promoto co-owner Frank Hadju has been in the motorcycle industry for almost 20 years now, and produced the first Oggy Knobbs kit back in 1999 after seeing something similar made by Yoshimura in Japan.

“We thought it was a good idea, we thought we could do it, and there was not much of it in Australia yet. So we got an old lathe and just started making them with hand-drawn paper sketches. Backyard engineering.”

That enterprise has grown into a business with high-tech equipment that sells its products around the country and internationally. Except for some anodising and other surface finishing, everything is done in house, using materials and services from other Aussie businesses whenever possible.

One competitive advantage they’ve got is quality. Some cheaper kits mount the knobs on M6 bolts – like those little ones around the crankcase – which makes them easy to fit but can actually cause worse damage in a crash. The Oggy Knobbs boys only use M10 bolts and sturdy brackets, making them stronger but sometimes more expensive to produce. The challenge then is convincing people to spend the extra money instead of going for a budget import. One of the classic problems for Aussie manufacturers.

At the same time the guys designed a fender eliminator and added race stand bobbins. Bring on the trackday! Or at least a chain clean and lube.

By MARK VENDER