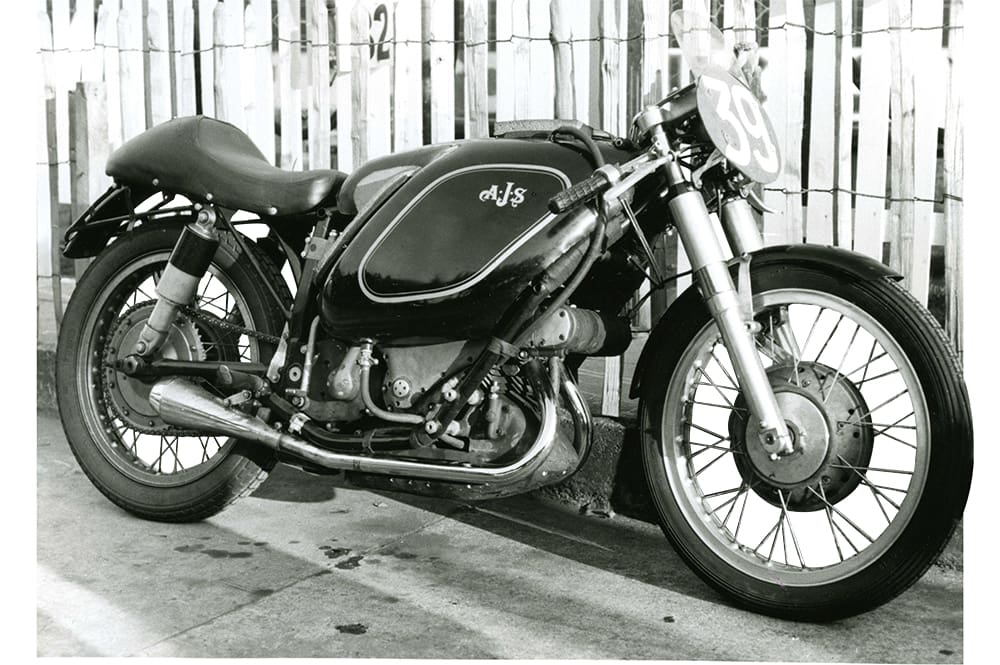

I was strolling through the paddock at a small club event and did a double-take; what the hell was an E95 Porcupine doing there? Only four of these AJS twins were built, and they made their debut at the 1952 Isle of Man TT. Two years later they were wearing huge pannier fuel tanks that made them unmistakable – and unmissable. Such exotica doesn’t come cheap. In 2000, an E95 sold at auction for £157,700 ($287K) and in 2011, Bonhams brokered a private sale at around US$675,000 (A$968K) for another.

I hunched down and took a closer look. That engine looks vaguely familiar… Nah, could it be a Laverda?

John Taylor, a 67-year-old who still keeps busy constructing agricultural buildings in the Lincolnshire Wolds, was watching from the shade of his Ford Transit, with a silly grin on his face.

“I’ve got an AJS 7R, a Matchless G45 twin and a couple of G50 singles,” he offers.

“I thought that it would be nice to have a Porcupine as well to complete the set. But I could never afford an original, so I decided to build a bike that looked like one instead. I’ve just finished it, and as I live only 10 miles away, I decided to bring it along to see how it goes.”

It certainly did go, although the Porcupine lookalike was never going to challenge real sprint bikes in the quarter-mile stakes.

“It’s over-geared at the moment,” admits John. “I need to put a bigger sprocket on the back wheel to give it better acceleration – even at my age I want to pick the front wheel up when I go over the mountain at Cadwell!”

With the sprint over, there was more time to talk to John at his farmhouse workshop.

“After a long day’s work, building motorcycles is the best way to unwind,” he explains. “As soon as [British soapie] Emmerdale comes on the telly, I say to my wife, ‘Right, love, I’m off up the workshop for a while’…”

Although he is clearly a big fan of AMC racebikes, he’s more than just a collector. His son Andrew won the Classic Racing Motor Cycle Club’s 350cc and 500cc GP Singles Championship in 2011 and again in 2012, usually riding Manx Nortons prepared by sponsor Tony Dunnell. Meanwhile, John prepared the AJS and Matchless singles that took Andrew to several wins in the Lansdowne Classic Series for original-spec, pre-1963 race bikes.

“That nice Aussie chap Cameron Donald partnered Andrew on my G50 for the Barry Sheene Memorial Trophy at Goodwood in 2011,” says John. “We had a problem with the bike on Saturday, but Cam won the race on Sunday!”

John’s plan to make a Porcupine lookalike started to take shape when he found a Laverda 750SF engine.

“Like the E95 engine, the Laverda is a unit-construction twin with inclined cylinders and the final drive on the right,” he explains.

“I had a spare G50 frame in case one of the racebikes was damaged, so it didn’t take me long to check if the SF engine would fit.”

You need to be committed to building your dream bike before you reach for the hacksaw and start cutting the twin downtubes from a perfectly good Matchless frame. John didn’t think twice.

“The downtubes had to be replaced with oval-section tube,” he says. “And of course the front of the frame is much wider.”

Both tubes that run from the nose of the seat to the swingarm gusset plates are unique to the Porcupine frame and are also oval, but the tubes running under the engine are round section. The forks are standard G50, while the rear dampers are AMC’s famous ‘Jampots’. As John pointed out, the Jampots were never very good and none of the factory riders wanted them, but AMC paid their wages so they didn’t have much choice.

The rear-wheel hub and brake were cast in magnesium using the original patterns.

“I sent the patterns to UK Racing Castings in Kent and asked them to make me three sets, so that I had a couple of spares just in case. The castings were machined by a chap in the Midlands who used work for Associated Motor Cycles. He also machined the brake for Rob Iannucci’s Team Obsolete bike, so I couldn’t ask for better.”

John then made a dolly and pressed the alloy covers that fit on the right side of the hub.

“The patterns for the correct twin leading-shoe front brake don’t survive,” says John. “The brake drum should have six cooling fins, but those are very hard to find, so I used one from a G50 to get my Porcupine running.”

He strolls over to a cupboard at the back of his workshop and reaches inside. “But I managed to buy one a few weeks ago. It wasn’t cheap…”

To make sure that his lookalike was built to scale, John had a friend print half life-size photographs of Rob Iannucci’s bike, using the 20-inch wheel rims as a reference. And that was important when it was time to make the Porcupine petrol tank.

Holding a massive 24.6 litres, it is instantly recognisable and a work of art. So who made it?

“I did,” says John, with so much modesty that he almost blushes. It was his first attempt at metal bashing. “Because I build agricultural buildings, I often have off-cuts of 75 x 225mm timbers. So I screwed and glued them together,” he explains.

“When I had a block of wood that was bigger than the tank I attacked it with my chain saw. Then I go to work with my planing machine and filled and filed it with a hand sander so that it was perfectly smooth.”

John’s next move was to get an aluminium sheet, lay it over the wooden anvil, and start beating it into shape with a rubber hammer.

“I used four sheets to make the top of the tank,” he says, “and when I was happy with the shape I welded them all together.”

Meanwhile, John had dispatched the SF engine to Keith Nairn of Laverda Scozia, who significantly lightened the crank to bring it to SFC race specification by machining away more than four kilograms of metal. Keith also cut off the starter clutch and dynamo drive – the lookalike would be bump started like a real Porcupine – and fitted Carrillo rods and his own forged pistons, before dynamically balancing the crank.

“I worked on the head myself,” adds John, who also fitted Mikuni carburettors in place of the original Dell’Ortos.

When British Racing Motors (BRM), the Formula 1 car constructors based in Bourne, Lincolnshire, sold much of the factory contents, John was able to buy several sheets of 10mm thick magnesium alloy.

“I cut those into the shape of the gearbox and engine covers,” he says.

The ‘Porcupine sump’ is a sheet of aluminium alloy that was beaten into shape on a lump of wood. It is mounted in front of the Laverda’s sump, and acts as a catch-tank for the engine breather pipe.

Check out the cam box cover that you can see between the front downtubes of the frame. It is made from an aluminium tube. John used his lathe to machine the cooling fins, then cut the tube in half lengthways and welded one piece to an aluminium box.

“Look closer and you can see oil pipes leading to it,” says John. “It might look like a Porcupine cambox but it is actually an oil cooler for the Laverda engine!”

Another bit of fakery is the outboard clutch.

“This one is a modified Honda 500 clutch,” explains John. “It doesn’t transmit the power, of course. The Laverda clutch is inside the engine.”

He made his own ignition sender system using Interspan components, and hid it behind the disc – that is, in front of the clutch. On the original bike this was the geared primary drive cover.

“That disc started life as a 180mm backing plate for an angle grinder. It was a rush job,” confesses John. “I spent 18 months working on my lookalike and I just wanted to get it finished.”

So is he happy with his Porcupine?

“Building this bike has given me a lot of pleasure,” says John. “It turned out better than I ever hoped it would. Now I want to put some miles on it before I take it to Cadwell. There’s a mountain there I want need conquer!”