To celebrate 20 years of Yamaha’s game-changing YZF-R1, local motorcycle journalist and bike builder Mark Boxer has built the ultimate tribute. He has seamlessly shoehorned the latest parts, technology, engine and even electronics of a 2018 model into an original 1998 chassis. To put this into perspective, remember that in 2009 Yamaha changed the R1 to suit its new crossplane big-bang engine, and in 2015 there was a MotoGP-inspired redesign that included sophisticated electronics. This makes the 2018 model a vastly different machine.

It looks like you’ve built the ultimate retro. Is that a fair description?

I call it retrotech. It retains its original retro look, but is fitted with all-new technology. Every mechanical component from 1998 has been removed and replaced with the corresponding one from a current R1, including the electronics. I’ve dubbed it the WE/98. WE is the model code used from 2015 onwards.

How did it come about?

I was approached by a company to build some bikes to promote certain product brands they sell.

Me being me, I decided to pitch a crazy idea. The R1 was actually launched in Australia at Phillip Island in 1998, so it seemed appropriate for Australians to honour it in this way. Amazingly, after some discussion and some crunching of numbers, I was given the go ahead.

What happened next?

In December 2017 I bought a mostly standard 1998 R1 that ran okay, but was in need of some TLC. A month later I took delivery of a donor bike, a new R1 with only 20km on the odo. I faced the moment of truth and stripped down both bikes to build one. Luckily, long before this I’d had access to a 1998 and 2015 R1, both with the engine out, so a lot of feasibility checking had already been done. The really hard part was to make it all look like a brand new bike.

But the technological advances over the 20 years have been mammoth.

It was challenge after challenge. One of the biggest was fitting the big-bang engine into the old frame. We managed to do this with custom engine mounts, but without cutting into the main original frame spars.

That wouldn’t have been a five-minute job.

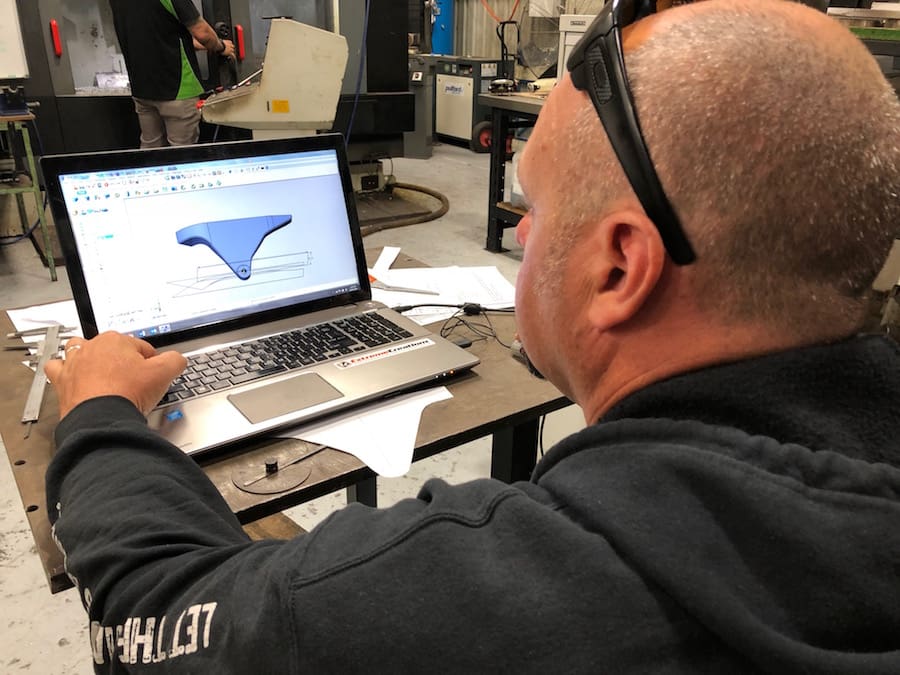

Luckily I had some expert help from Ben Shaw, a man very well known for his incredible CNC-machined motorcycle parts. Together we designed new billet side engine mounts. With lower ones made at Solid Engineering, and some amazing TIG welding by Solid’s owner, Cameron Lees, the 2018 engine was finally mounted into the 1998 frame.

What about adapting modern electronics to a last-century motorcycle?

There were a load of jobs to do and not a great amount of time to get them done. Rather than trying to fabricate and do wiring at the same time, I handballed the electrics to Tony from Race Bike Services, who made the necessary changes to the loom to make it fit. I was able to use all the original 1998 lights and indicators, but to match the retrotech theme, I fitted them all with Philips CAN Bus-compatible LED bulbs.

Looking at details like the 1998-style fuel tank makes me think this project just kept throwing curve balls at you?

The fuel tank actually is the factory 1998 item, but I had to heavily modify the underneath to make it a similar half-tank set-up to a new one. This was because the current-model airbox is taller than the old one, as it features adjustable-length runners and secondary injectors. So the whole inside front section of the 1998 tank had to be removed and a new front wall made.

There must be a lot more hidden details like that.

One example is the rear subframe. I fabricated a base plate to mount the new battery tray IMU, as well as the ABS unit and other electronics. I even mounted the late-model tool kit with two little hex keys. That and the detail machining you see in the current R1 head stem has been replicated on the 1998 head stem, which was modified and used with the 2018 triple clamps.

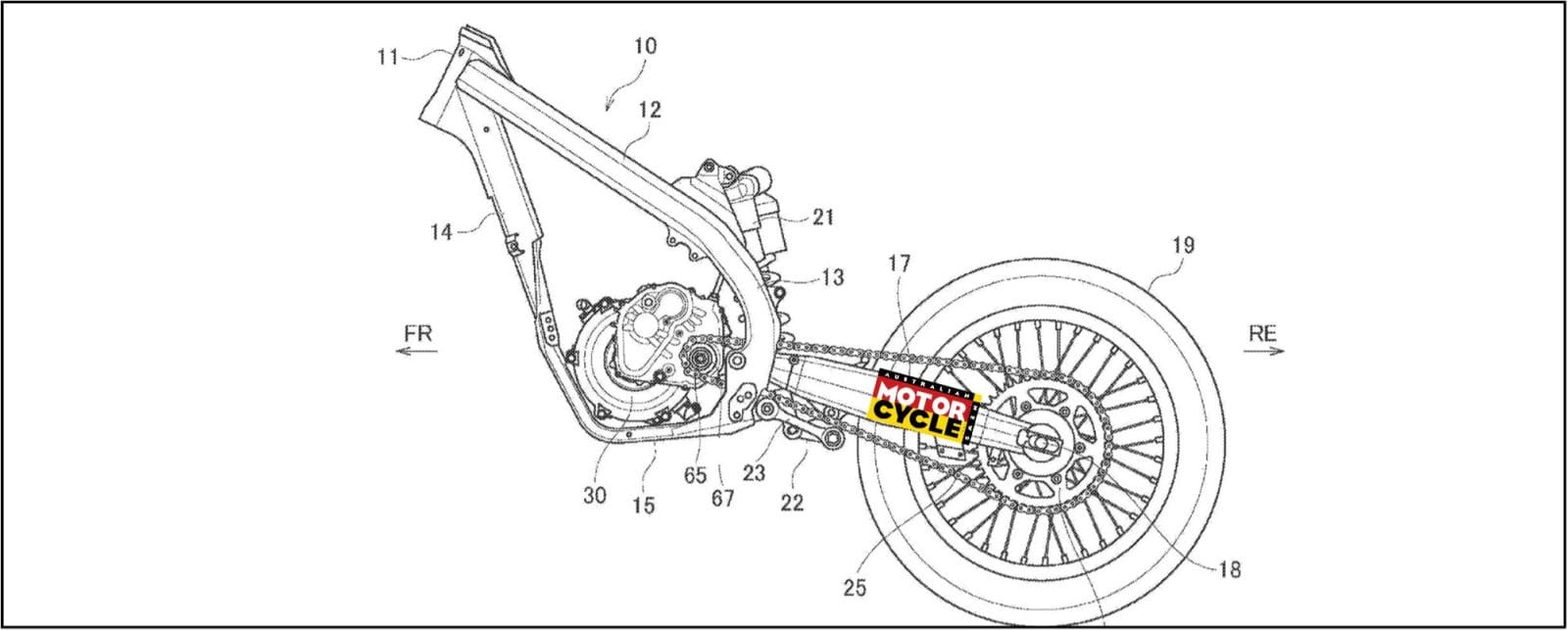

Talk us through fitting the 2018 swingarm?

It took some machining and custom spacers to make it sit nicely in the 1998 frame. The hardest part of the swingarm swap was making the suspension geometry work so that things didn’t hit, but also ensure the suspension worked properly. The original suspension linkage and dog bones needed to be replaced, and new ones were made with the help of the guys at Solid Engineering and their CNC machine. This is typical of a lot of work we did.

Many little changes had to be done around the bike to ensure everything had a factory-like fit. For example, I had to modify the front fairing support so that the new instrument cluster could be fitted. It all seems like a blur now, but I definitely spent a lot of hours, long days and late nights, on it to make sure things fitted nicely and worked properly.

How long did the build take?

About three months. I stripped the first bike on 15 February and the WE/98 was completed on 16 May. In that time I was away for about two weeks as well!

As mentioned, everything was left standard apart from R&G crash protection, Ipone fluids, Vesrah brake pads, a DID chain, JT sprockets, Yuasa battery and Dunlop 212 tyres. Then I was given a cool-looking Oxford Products paddock stand to sit it on, and a stretch cover to keep it clean.

An amazing effort. Congratulations.

Thanks. By no means will it be better or even expected to be as good as a brand new R1 given the 20 years of development in the newer chassis and fairings, but it’s a huge buzz knowing you’re riding an old bike with everything from a brand new one. A massive thanks goes to all who helped, and to Ficeda for having the faith in me for taking a crazy idea and making it a reality!

WIN THIS R1!

Every dollar spent on Ficeda products at your local stockist buys a ticket in the draw to own this amazing creation! Entries close 5pm on 19 October, with the prize drawn on Friday 26 October. Visit www.ficeda.com.au win for full details on how to enter.

By Hamish Cooper