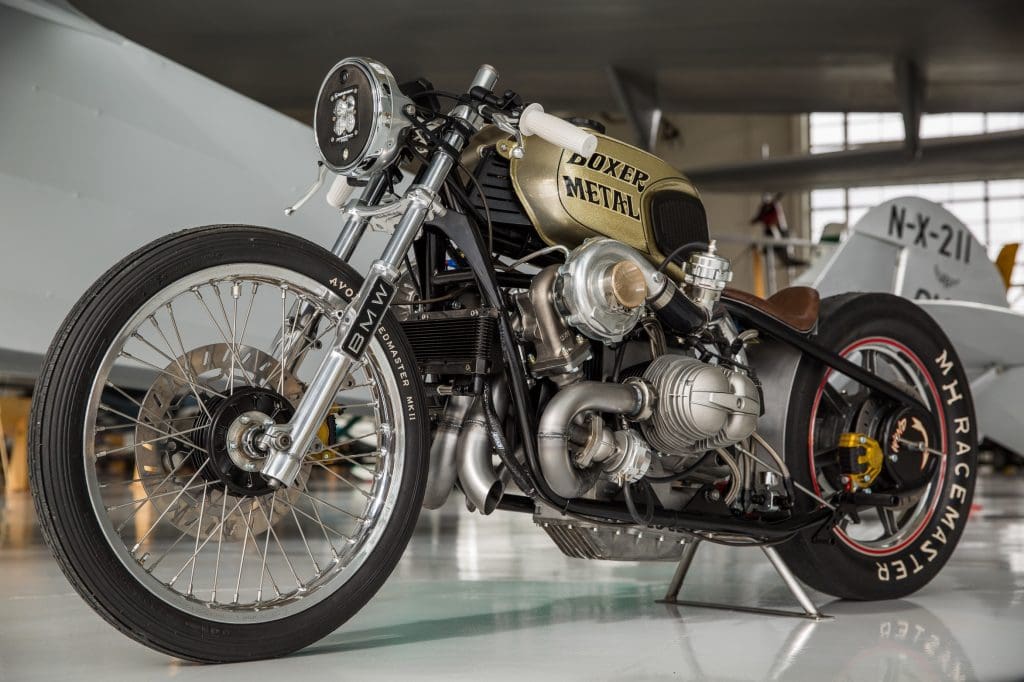

Yet Chris Canterbury, founder and owner of Boxer Metal in California, still managed to knock one out of the park with his fantastically unique 1980 BMW R100 twin-turbo build.

“We were invited to the One Moto Show in Portland, but the bike that would have been perfect for it was already packed and shipped to Guatemala,” says Chris. It didn’t make things easier that the One Moto Show was just seven weeks away. Not afraid of a challenge, Chris set out to not only build a bike for the show, but to build something that would really stir things up. It takes a great deal of ingenuity to fuse one turbo to any bike, but two is more than any engineering-obsessed kid could ever wish for.

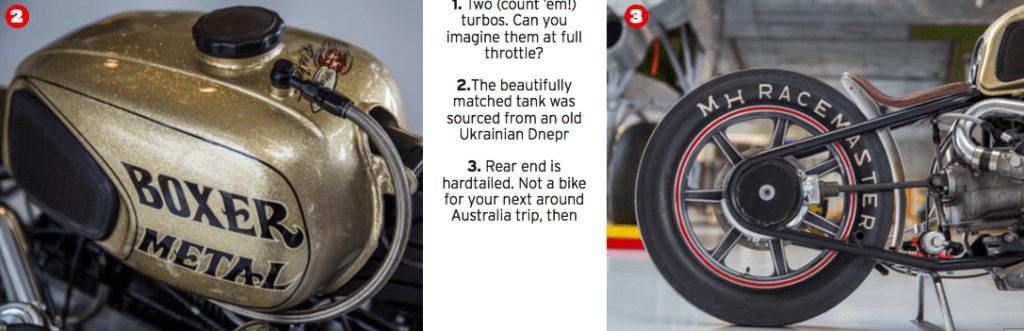

Chris and his partner Rebecca met through work at BMW Motorcycles America. After hours, Chris would tinker away on vintage Beemers. Obviously this fuelled his passion for BMW restoration and customs that would see him still happily getting oil under his fingernails a full 30 years later.

Growing up in the 70s, Chris had always loved the era’s drag racing look. He built a rigid BMW bobber in 2014 and found himself really wanting to take on another. “Anyone can do a single turbo,” he quips.

“So I decided to do two turbos and to make it fuel injected.” As you do.

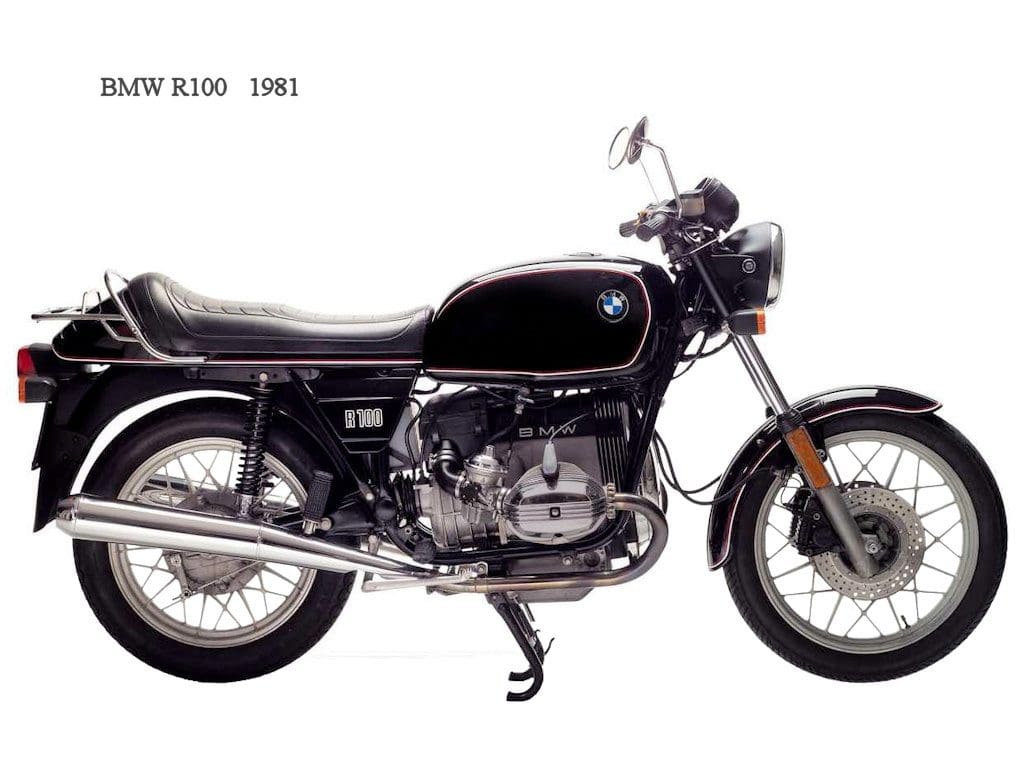

What’s it based on?

The original versions of the bike were added to BMW’s line-up in 1977 as part of the ‘slash 7’ model range. The older R90 models were replaced with an R100, R100S, and a pair of fully faired R100RS and R100RT options. Testing at the time put the power at between 65 and 70 ponies (around 50kW).

But none of this was of much interest to Chris, as he had accepted the bike as a trade-inor some previous custom work. “The thing had clearly had a rough life. This included some time spent with a sidecar attached. After we opened her up, we found that the crank and connecting rods were on their last legs as well.” But Chris had made his bed and he was going to have to sleep in it. It’s all he had laying around the shop, and pretty much the only thing that would allow him to build something decent in seven weeks.

What’s it got?

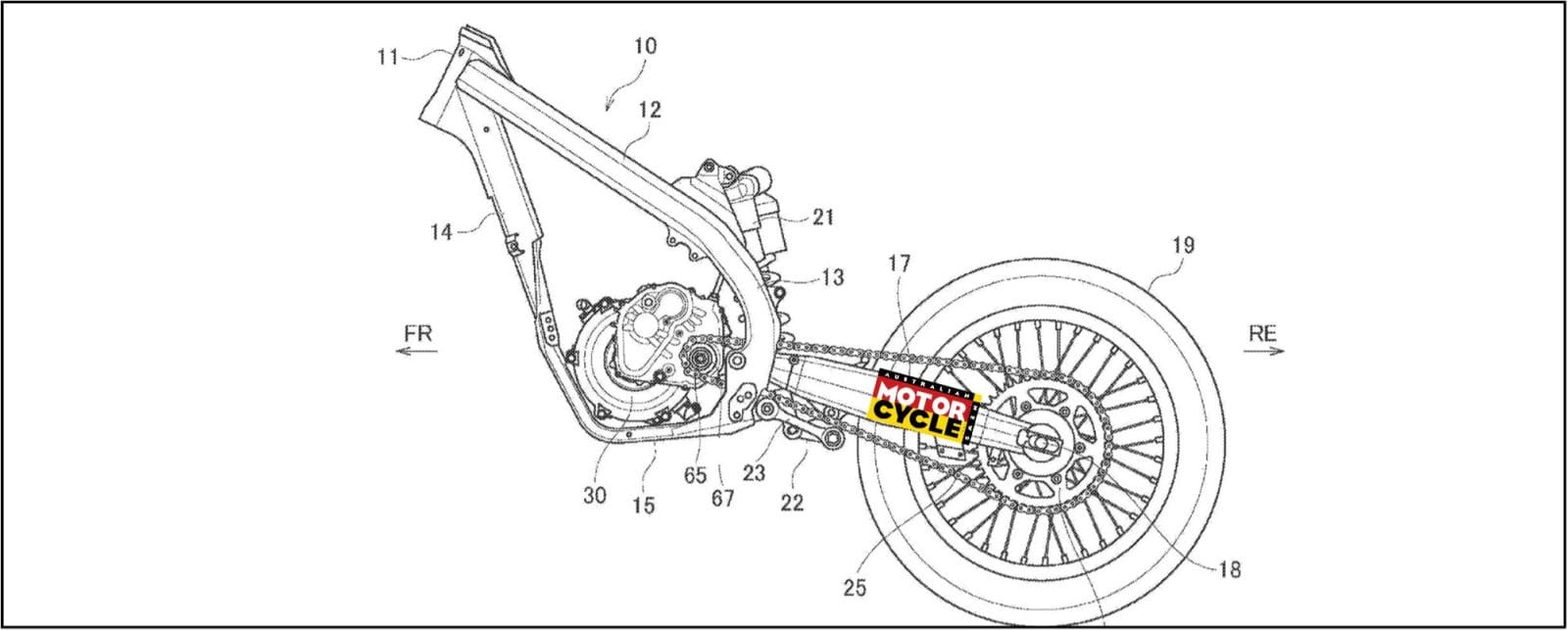

Chris started with the stock frame and went to town by lengthening it by 125mm, lowering it by 75mm, and then sending the rear suspension to the big Motorrad Haus in the sky. He also added cross bracing between the engine and the frame for some much-needed rigidity against the impending torque tsunami.

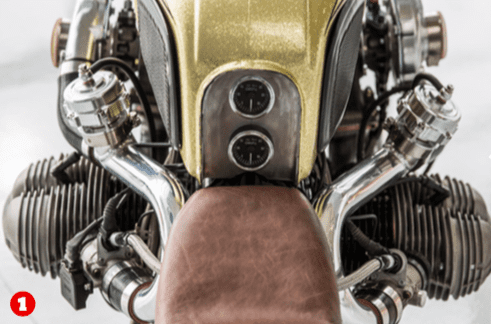

“The engine was completely freshened up. We also added a new crank and a set of conrods,” says Chris. “We lowered the compression to 7.2:1 and replaced the stock BMW throttle bodies with newer units froman R1150GS. We then machined the fuel line fittings and used the ‘Megasquirt’ and ‘Microsquirt’ gear to handle the injectors, throttle position sensor, and both the O2 sensors. It’s all programmable from a laptop, so it really makes things easy.” Chris says that the rest of the injection system and the specs on the custom-made turbos are all a little ‘hush-hush’.

The shop will have a video up on YouTube of the final, dialed-in bike some time in the next few months. Dare we say that it’d probably be one to add to your watch list – and your ‘listen’ list, too.

What was tricky?

As with any turbo build, there are two bloody big mountains all builders have to climb: Mt. ‘Space’ and Mt. ‘Bang’. All that extra equipment and piping is hard enough to fit in the engine bay of your average Commodore, let alone the lunch-boxed sized vacancies in and around the old Beemer’s Boxer ears. And that’s before you start to worry about the engine’s ability to handle it all.

“The tricky part was designing the frame so there was room for the two turbos and all of the plumbing. So, due to the show’s time constraints, we left the engine’s fine-tuning until afterwards. The other challenge was the single master cylinder for both front and rear brakes. There’s a line-lock solenoid to allow for burnouts as well as a proportioning valve to make sure each caliper is getting the correct brake pressure. It was a real pain to get right.”

What’s next?

While the bike took the top BMW award at the show, it’d all be for naught if it didn’t actually run. So now Chris is rolling up his sleeves and taming those big, spinning monsters.“There’s three things left on the list: setting up the turbos, dialling in the injection, and building a centerstand,” he says.

Off the back of this, the shop is also working on a proprietary fuel injection system and single turbo kit for all BMW R100 models.“Then there’s a ‘top secret’ project for late 2016,” whispers Chris. If it’s anything like this, it sounds like Christmas for the world’s custom bike fans might come early this year.