Handling matters, especially in MotoGP. It is far harder to make a 1000cc MotoGP bike work in the twisty bits of a track than down the straights. And that is where the approach of Suzuki since its return to the MotoGP paddock has been so exemplary.

We have watched many companies come into the class with engines that produce serious amounts of power, then struggle to make the bike work in the corners. Ducati has been a serial offender on this point, something it has only recently worked out. Last year Honda fell into the trap, too. Compare that with Yamaha: Jorge Lorenzo was only 16th fastest in a straight line at Mugello last year, but won the race by over five seconds.

Handling, then, matters a lot.

Suzuki has clearly decided that power comes second. The bike has handled extremely well from the start, and now power is slowly being increased, but only if it doesn’t affect the handling. Just getting to that point, however, has required a lot of careful thought.

Current racebike design is influenced by the tyres, and with control tyres you would normally be aiming your design at a static target in terms of tyre design. But these are not normal times. We have recently moved from a seven-year dalliance with Bridgestone to Michelin, and it is clear that the French company’s designs are anything but set in stone at the moment.

If you can build a carefully thought-out bike, you should be able to get a base that can be modified to work with quite a few different tyre designs. Yamaha manages to do it with its current chassis being basically the same as the one that raced and won the championship last year.

To get a design that can work well in ‘most’ situations you need a really good understanding of the way a MotoGP bike works on track. It’s far more complex than a racing car and very few people have a handle on the general principles and how each of those principles relate to each other.

Suzuki has clearly done a lot of research, right now all that seems to be needed is a little more power. In Qatar the bikes were 10km/h down on top speed, by Austin that had dropped to five; Jerez with its nightmare tyre choices wasn’t so good, but that was partially down to a lack of off-corner grip.

What the Suzuki does particularly well is approach a corner and turn. It’s an area that is really complex in terms of the various demands made on the chassis. The bike has to be able to brake very hard, so the chassis needs to be very stiff to remain stable under the heavy braking loads. The same as the bike rolls into the corner – first the countersteer the wrong way, then the steer through the corner. Bear in mind that in MotoGP the transitions from full upright to full lean are the fastest in the sport; it’s one of the main places where MotoGP bikes improve their lap times over other forms of bike racing so this is a very violent manoeuvre.

Once the bike is over at full lean, however, there is a very different set of requirements. At a little over 60º of lean the suspension is quite compressed – just as on a banking aeroplane, the G forces through the centre of the vehicle increase with the cornering forces. At 60º they are 2G, by 72º they are 3G. That means a bike and rider combination weighing 240kg upright is forcing down on the springs at 480kg at 60º. Spring rates have to be chosen to work well under these forces. Even if we didn’t have this increase in load the suspension wouldn’t work very well in any event as the suspension is simply working in the wrong direction. To deal with bumps on the track or road the chassis has to flex a little.

It’s easy to build something that is light and flexible. And it’s relatively easy to build something that is very rigid. But it’s not easy to build something that is rigid in one plane and slightly flexible in another. Getting both of those right while also finding a way to accommodate the engine, rider, fuel, the correct centre of gravity position and ground clearance really isn’t easy.

To date the best approach has been carefully designed and welded aluminium beam chassis. They are designed to be resistant to twist, quite stiff under braking, and relatively soft laterally (while leaned over). Yamaha uses big and complex CNC-machined sections welded together, while Honda uses a combination of stampings and CNC-machined sections but both require significant design compromises. Using one aluminium structure, it’s very difficult to increase braking rigidity without also affecting lateral stiffness or torsional stiffness.

Yamaha has stuck with an in-line four-cylinder design since the start of MotoGP, resulting in an engine that is wide but very short. It gives Yamaha a lot of flexibility in placing the centre of gravity in the right place. Reversing the crank rotation had the effect of allowing a quick roll into a corner by reducing gyroscopic stability.

The width, however, has been a problem. Four cylinders all in a row are a serious block to cooling air passing through the radiator. Not only is the engine itself in the way but so are the long front engine mounts deemed necessary to brace the front of the chassis for braking stability while also allowing some flex while leaned over.

Yamaha has followed a strategy of making an ever thinner section ‘web’ as a side beam to try and get the right combination of flexibilities and also to get air in through the radiator and out again.

Honda’s preference is for a V4. That gives the best power with almost no compromises, it’s narrow, so cooling isn’t an issue, and it rolls into corners very nicely. It is however a 90º V, so it’s quite long, and the inlet system is difficult to package in, restricting where Honda can place it in the chassis. Honda has also used quite short front engine mounts for several years now, restricting the bikes’ ability to keep the flex they require for leaned over grip as well as the front-end rigidity required to keep the front stable under heavy braking.

For a while Ducati decided that braking stability was the most important thing, seemingly to the exclusion of almost everything else. Its carbon fibre ‘structural airbox’ chassis was very stable under braking, but it required all the considerable skill of Casey Stoner to make it work in the corners. That style of chassis has very little lateral flex, so doing well in races was down to the cat-like reactions of Casey saving the bike from a series of front wheel slides.

Suzuki has found a different way.

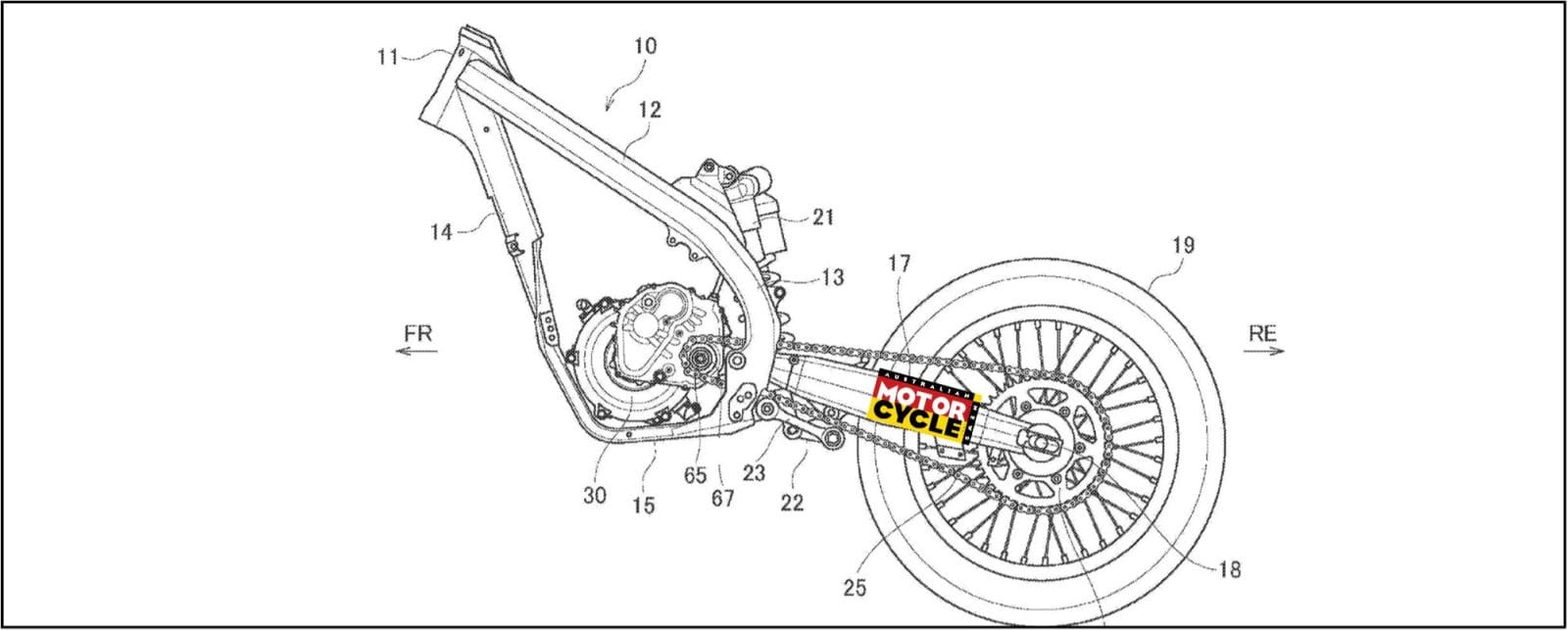

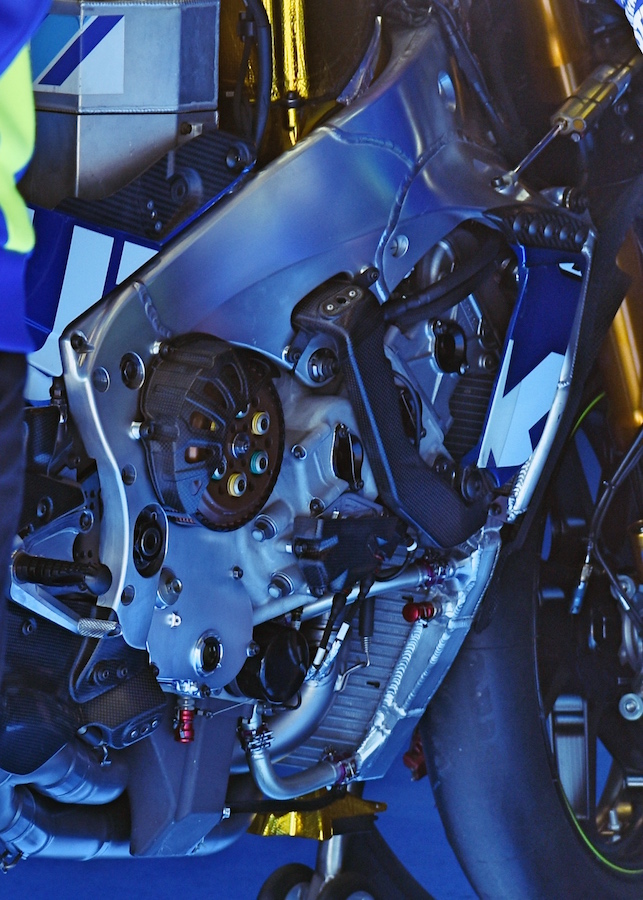

It decided to use an in-line four for its return to MotoGP, but knew that the bikes needed a better compromise between engine width, cooling and the various different rigidities required. The answer was a chassis made of both aluminium and carbon, using shapes not previously seen on the MotoGP grid.

The main beams of the Suzuki chassis look like they are conventional aluminium beams once the fairing is on, but all isn’t what it seems. The front section of those beams is very different – much deeper in section, they have a ‘wing’ type shape around the steering head designed to make up for a lot of the braking stability usually lost with a conventional ‘bend round the cylinder head’ type chassis. Behind the radiator the aluminium is almost horizontal and the steering damper is mounted on a vertical stud.

The trickery doesn’t stop there. On a normal MotoGP bike the front engine mounts are very low, usually just in front of the centre of the crankshaft. This allows the beam to be strong enough to help brace the steering head while still being laterally flexible enough to handle and grip well in the corners. The Suzuki has the same sort of low engine mounts, but rather than use an aluminium extension of the chassis, a thin blade-like carbon fibre strut joins the main beam and the engine.

The outside face of the carbon fibre strut looks like part of the fairing from the outside, and is a ‘bolt on’ replaceable part in the event of a crash. Five bolts hold the top of the ‘blade’ to the main beam and a conventional mount is at the bottom. The strut forms the front of the radiator exhaust duct hole.

Because the carbon strut is so thin it forms a very rigid structure joining the engine to the chassis under braking, but that same thin section allows the mount to flex laterally at full lean much more easily. The aluminium main section, however, has the natural tendency to damp out any spring reaction in the main structure. It is for this reason that the precise specification of the aluminium used in race motorcycle frame design is kept secret by each factory.

In one major design change, Suzuki has braced the steering head so it is more rigid, allowed a ‘tuneable’ chassis strut to the lower engine mount, and managed to retain more braking stability while simultaneously maintaining the lateral flex in the main beam required for hard cornering. Almost as a bonus there is a far bigger airway for escaping radiator exhaust air.

The Suzuki is getting very close – the Le Mans podium for Maverick Viñales proved that. Just one more engine upgrade and it will be capable of staying with Yamaha. The only other thing required then is a top rider. Viñales may have jumped ship, but with the bikes rapidly improving, there will be no shortage of gun riders lining up to replace him.

by NEIL SPALDING PHOTOGRAPHY GOLD & GOOSE